- Home

- >

- Products

- >

- Pin Gear Coupling

- >

Pin Gear Coupling

1.Pin gear coupling is an essential component in the mechanical transmission system, ensuring reliable power transmission in various industries.

2.Pin gear coupling enable efficient operation, increasing the productivity and performance of equipment in the metallurgical industry.

3.Pin gear coupling provide the necessary reliability for connecting disparate equipment, resulting in smooth operation and productivity of production equipment.

If you need such products, please contact us. Our shop offers a wide range of options to meet your specific needs.

- Information

Another Name for pin gear coupling:

1.gear coupling with elastic pin

2.elastic ring coupling

3.hydraulic gear coupling

Product Description:

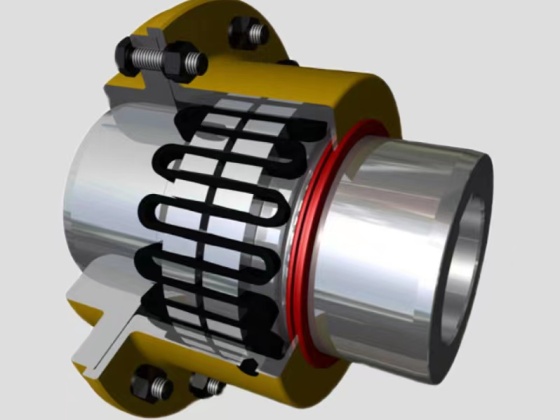

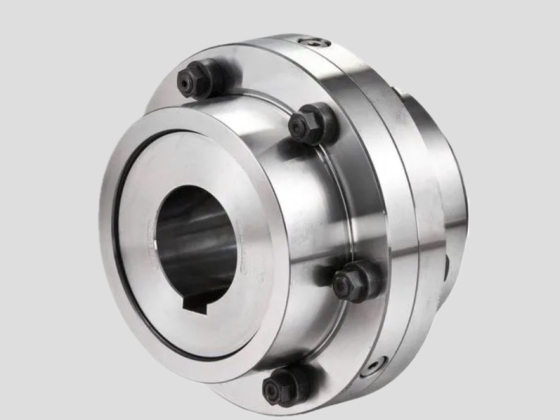

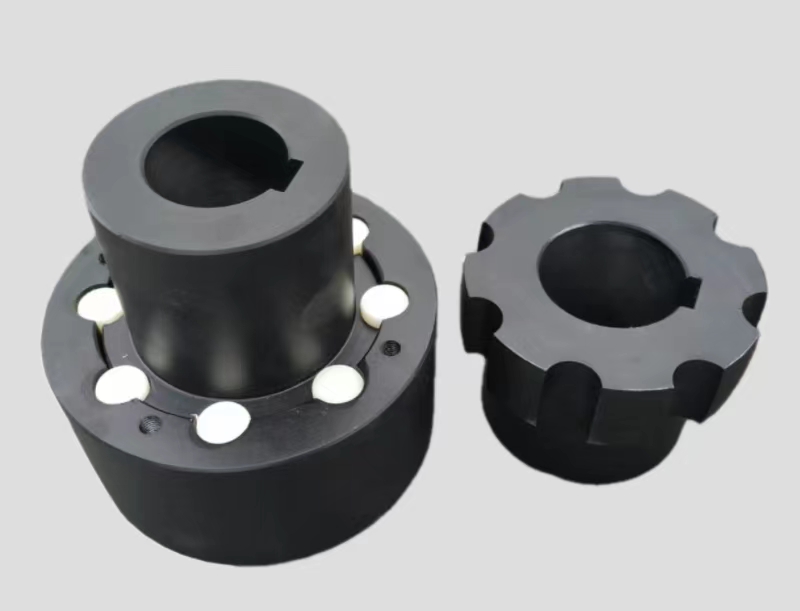

Pin gear coupling is a common mechanical transmission device, mainly used to connect two axes and transmit rotational power between the axes. It usually consists of two bushings, two gears, pins and two coupling covers. The design of this coupling allows it to operate at high torque, speed and load, making it widely used in many industrial applications.

Features:

1.High load-bearing capacity: gear coupling with elastic pin can withstand large torques and loads and are suitable for high-power transmission.

2.High transmission efficiency: Because the gear coupling with elastic pin adopts a meshing transmission mechanism between gears, its transmission efficiency is high and it can accurately transmit power.

3.Stable and reliable: gear coupling with elastic pin operates smoothly and reliably, and is suitable for situations where continuous and stable power transmission is required.

4.Wear resistance: The gears are made of high-quality alloy steel, which has strong wear resistance and can work stably for a long time.

5.Strong adaptability: elastic ring coupling suitable for various engineering machinery, metallurgical equipment, mining equipment, cold rolling mills, conveyors and other industrial fields.

Product application industries:

1.Engineering machinery: hydraulic gear couplings are often used in the power transmission systems of engineering machinery such as excavators, loaders, bulldozers, etc. to ensure reliable operation of the equipment.

2.Food processing: In the food processing and manufacturing industry, hydraulic gear couplings are widely used in production equipment such as mixers, mixers, and grinders to ensure the effective operation of production equipment.

3.Metallurgical equipment: hydraulic gear coupling are used in various metallurgical equipment, such as rolling mills, finishing mills, coolers, etc., to transmit power and ensure efficient operation of the equipment.

4.Papermaking equipment: In the papermaking industry, hydraulic gear coupling are used to connect various paper reels, cutting machines, packaging machines and other equipment to ensure the production and finishing of paper.

5.Mining: In mining equipment, elastic ring couplings are used to connect conveyor belt machines, crushers, screening machines, etc. to realize the transportation and processing of ore.

6.Textile machinery: In textile production lines, elastic ring couplings are used in various types of spinning machines, looms, sewing machines and other equipment to ensure efficient processing of fiber materials.

7.Automation equipment: In automated production lines and robotic systems, elastic ring couplings are widely used in various types of automatic assembly machines and conveyor belts.