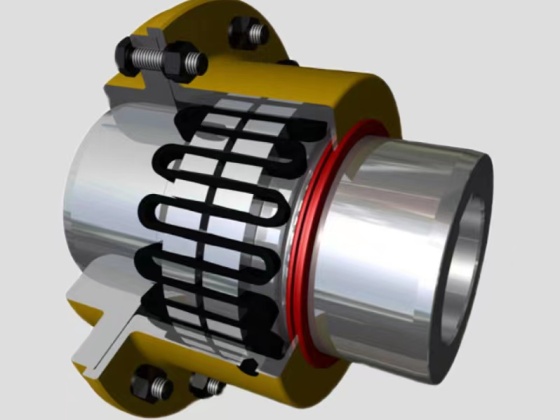

Friction Safety Coupling

1.The friction safety coupling are designed to provide reliable power transmission, ensuring smooth operations and preventing damage to machinery.

2.The Steel ball coupling are a popular choice for power transmission applications due to their exceptional strength and durability.

3.The expansion coupling sleeve type are widely used in heavy-duty machinery and equipment where precision and robustness are required.

4. With the power transmission friction safety coupling unique features and ability to withstand high loads and compensate for misalignment, these couplings provide the necessary flexibility and durability in demanding environments.

If you need such products, please contact us. Our shop offers a wide range of options to meet your specific needs.

- Information

Another name for friction safety coupling:

1.steel ball coupling

2.expansion coupling sleeve type

3.power transmission friction safety coupling

Product description:

The expansion coupling sleeve type is a type of torque-limiting coupling, which adds some friction plates to the structure to limit torque. This coupling uses a double-row roller chain to connect the two sprockets. By tightening the adjusting nut, the disc spring and the pressure plate compress the friction plate between the sprockets, and finally the torque is transmitted by a certain friction force. They can slide relative to each other in case of overload, thereby protecting the mechanical device.

Product advantages:

1. Prevent equipment overload: The steel ball coupling is in the transmission system. When the torque is too large or the load is suddenly too large, the safety friction coupling can automatically separate, thereby preventing the equipment from being damaged due to overload. .

2. Prevent the rotor from breaking: The expansion coupling sleeve type is to prevent equipment damage and protect personal and equipment safety through automatic disengagement.

3. Achieve rapid mechanical protection: Using safety friction couplings in the transmission system can not only extend the service life of the equipment, but also provide rapid mechanical protection for the equipment.

4. Improve production efficiency: The use of power transmission friction safety coupling in the transmission system can ensure that the equipment extends the operating period and reduces downtime, improves the reliability of the equipment, and increases the production efficiency of the equipment.

Product application scope:

Safety friction couplings are widely used in various industrial and mechanical equipment, such as wind turbines, locomotive traction transmissions, machine tool spindles, metallurgical machinery and other transmission systems.