- Home

- >

- Products

- >

- Drum Gear Coupling

- >

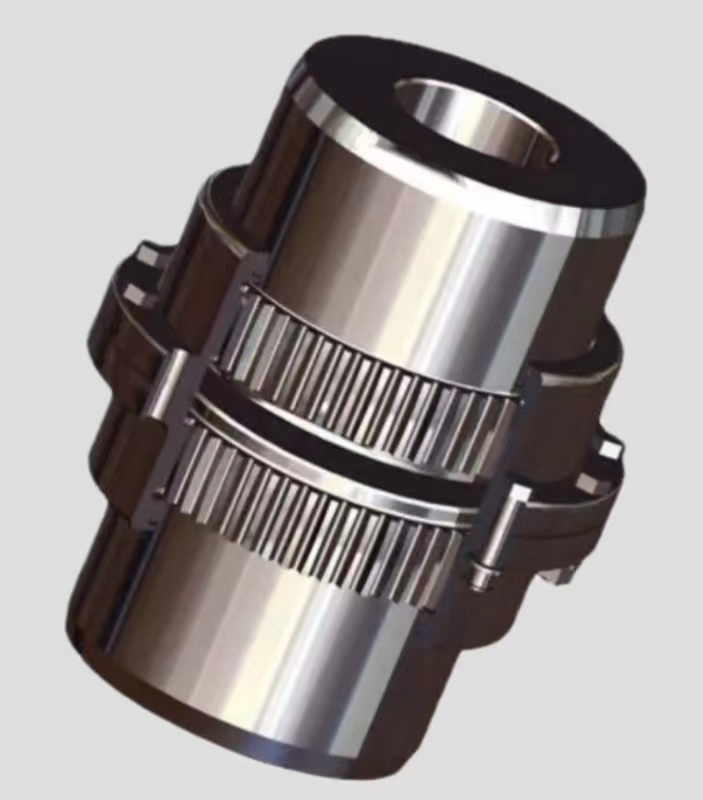

Drum Gear Coupling

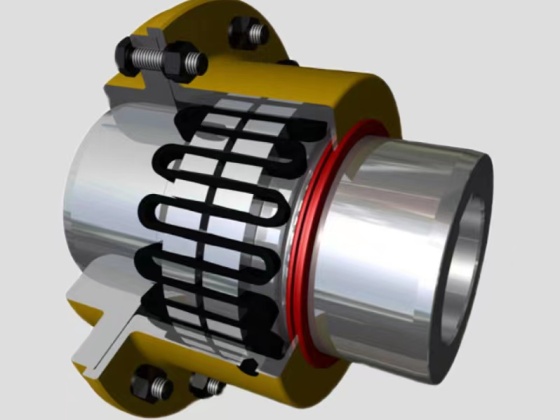

1.With their ability to accommodate misalignment and compensate for axial movement, drum gear coupling with nylon sleeve ensure reliable and efficient operation.

2.For applications requiring added protection and durability, drum gear couplings with nylon sleeves offer excellent performance.

3.The nylon sleeve provides enhanced resistance against wear, corrosion, and harsh operating conditions. The power transmission drum gear couplings are specifically engineered to withstand heavy loads while maintaining smooth power transmission.

If you need such products, please contact us. Our shop offers a wide range of options to meet your specific needs.

- Information

Another name for drum gear coupling:

1.telescopic drum gear coupling

2.drum gear coupling with nylon sleeve

3.power transmission drum gear coupling

Product Description:

The drum gear coupling is a rigid-flexible coupling. The gear coupling is composed of an inner ring gear with the same number of teeth and a flange half coupling with external teeth. External teeth are divided into two tooth shapes: straight teeth and drum teeth. Drum gear couplings can allow larger angular displacement (relative to spur gear couplings) and can improve the contact conditions of the teeth and increase the transmission torque. Drum gear coupling extends service life.

Features:

1. Strong load-bearing capacity: Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-bearing capacity of the drum gear coupling is 15 to 20% higher than that of the straight gear coupling on average.

2. Large angular displacement compensation: When the radial displacement is equal to zero and under the same module, number of teeth、 tooth width and the angular displacement allowed by drum-shaped teeth is larger than that of spur teeth.

3. The drum-type gear coupling improves tooth surface friction and wear, reduces noise, and has a long maintenance cycle;

4. The tooth ends of the outer gear sleeve of the drum-type gear coupling are in the shape of a trumpet, making it very convenient to assemble and disassemble the inner and outer teeth.

5. Drum gear couplings are available in complete varieties and specifications and comply with corresponding standards.

6. Drum gear couplings are rigid, flexible, and inelastic, so they are not suitable for machines that require strict vibration reduction, buffering, and two-axis alignment.

Product Application Scope:

Drum gear couplings are particularly suitable for low-speed and heavy-load working conditions, such as metallurgy, mining, hoisting and transportation industries. It is also suitable for shaft system transmission of various types of machinery such as petroleum, chemical industry, and general machinery.