News Release: Fluid Couplings Drive Industrial Efficiency with Expanding Applications and Technological Innovations

2025-11-26 07:34News Release: Fluid Couplings Drive Industrial Efficiency with Expanding Applications and Technological Innovations

FOR IMMEDIATE RELEASE

1. Introduction: The Silent Workhorse of Industrial Machinery

In the heart of industrial operations, from mining to energy production, Fluid Couplings serve as critical components for power transmission. These devices, which transfer rotational force through a liquid medium, have become indispensable for their ability to ensure smooth starts, reduce mechanical stress, and protect machinery from overloads. As industries globally push for higher efficiency and sustainability, the role of Fluid Couplings continues to evolve, blending traditional reliability with cutting-edge innovations.

2. What Are Fluid Couplings? Principles and Advantages

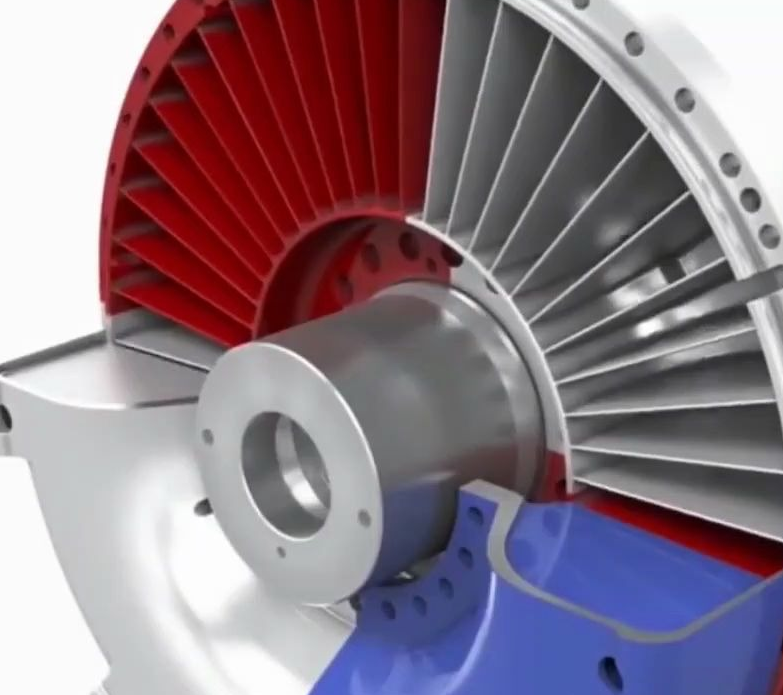

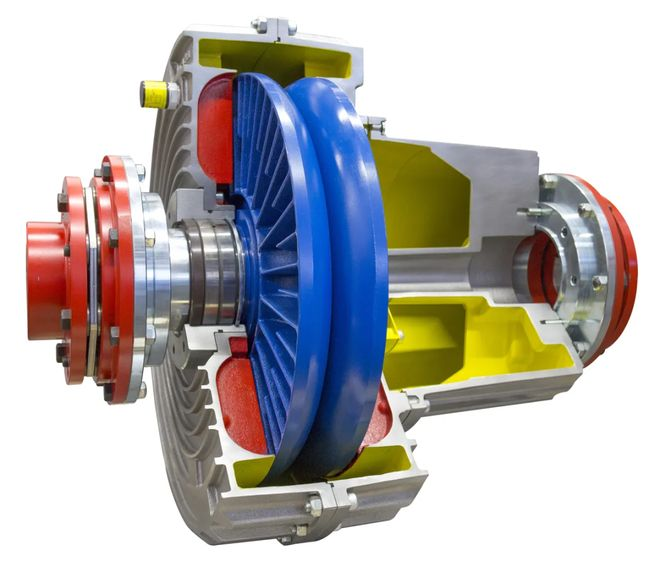

A Fluid Coupling is a hydrodynamic device that transmits power between rotating shafts using a fluid, typically oil or water. Its core structure consists of a pump wheel (connected to the input shaft) and a turbine wheel (connected to the output shaft), enclosed in a sealed casing. When the pump wheel rotates, it accelerates the fluid, generating kinetic energy that drives the turbine wheel—this process enables power transfer without direct mechanical contact .

Key advantages of Fluid Couplings include:

Soft Start and Vibration Damping: By gradually accelerating loads, they prevent sudden current surges in motors and minimize wear on drivetrain components .

Overload Protection: During jams or excessive loads, the fluid absorbs shock, and safety features like fusible plugs release fluid to halt transmission, preventing damage .

Adaptability: They accommodate misalignment and are suitable for heavy-duty applications, such as conveyor belts or crushers, where rigid couplings would fail .

However, Fluid Couplings have limitations, including energy losses through heat and lower efficiency at high speeds. Ongoing R&D focuses on mitigating these issues through advanced cooling systems and hybrid designs .

3. Diverse Applications Across Industries

Fluid Couplings are deployed across multiple sectors, demonstrating their versatility:

Power Generation: In thermal plants, Fluid Couplings regulate pumps and fans. For instance, the鄂尔多斯 Group in China retrofitted its boiler feed pumps with high-speed motor-direct drives paired with Fluid Couplings, cutting electricity consumption by 25%–50% and reducing plant energy use from 8.1% to 6.9% .

Mining and Metallurgy: Equipment like ball mills and crushers rely on Fluid Couplings to handle high-inertia starts. FLUDEX® couplings, for example, support conveyor systems in mining, enabling smooth operation under volatile loads .

Manufacturing and Heavy Industries: From cement production to chemical processing, Fluid Couplings drive mixers, compressors, and extruders. Their vibration-damping properties prolong equipment lifespan in harsh environments .

4. Technological Evolution and Market Trends

The Fluid Coupling market is transitioning toward intelligent and eco-friendly solutions. According to industry reports, the global market for variable-fill Fluid Couplings will grow from $616 million in 2025 to $807 million by 2031, reflecting a 4.6% compound annual growth rate . Drivers include:

Smart Integration: Modern couplings incorporate sensors and PID controllers for real-time monitoring, aligning with Industry 4.0 standards .

Energy-Efficient Designs: Innovations like magnetic-controlled Fluid Couplings and compatibility with cooling systems reduce slip-related losses .

Standardization Efforts: Initiatives such as China Mobile Design Institute’s "universal fluid connector" promote interoperability across brands, lowering costs and simplifying maintenance .

5. Case Study: Enhancing Safety in Material Handling

A Chinese cement plant replaced the mechanical clutch in its bucket elevator with a Mairuisheng hydraulic coupling.The results included:

40% reduction in startup current peaks;

Near-elimination of belt-snap incidents;

Maintenance cycles extended by over 30%.

The project highlights how Fluid Couplings mitigate operational risks while boosting productivity .

6. The Road Ahead: Challenges and Opportunities

While Fluid Couplings face competition from electronic drives and direct-drive systems, their unique ability to handle extreme loads ensures sustained demand. Future developments will focus on:

Hybridization: Combining Fluid Couplings with frequency converters for precision control .

Sustainability: Using biodegradable fluids and materials to minimize environmental impact .

Customization: Tailoring designs for emerging sectors like renewable energy and electric vehicle manufacturing .

7. Conclusion: Embracing a Fluid-Powered Future

As industries prioritize resilience and efficiency, Fluid Couplings will remain pivotal in power transmission systems. Their proven track record in safeguarding machinery, coupled with ongoing technologicrades, positions them as a cornerstone of modern industrial automation. For businesses seeking to optimize performance, investing in advanced Fluid Coupling solutions is not just a choice—it is a strategic imperative.

Media Contact:

Merisen

Marketing Director, Global Industrial Solutions

Email: info@mrscouplings.com

Phone: +86 13394151666