News Release: Fluid Couplings – Powering Industrial Efficiency with Smooth Operation and Protective Benefits

2025-11-10 16:02News Release: Fluid Couplings – Powering Industrial Efficiency with Smooth Operation and Protective Benefits

Introduction

In an era where industrial efficiency and equipment longevity are paramount, Fluid Couplings have emerged as a critical component in diverse sectors, from mining and manufacturing to energy and transportation. These devices, which transmit torque through hydraulic fluid, are lauded for their ability to enhance operational safety, reduce maintenance costs, and optimize performance. As industries increasingly prioritize sustainability and cost-effectiveness, the advantages of Fluid Couplings continue to drive their adoption worldwide.

---

Key Advantages of Fluid Couplings

1. Smooth Startup and Vibration Damping

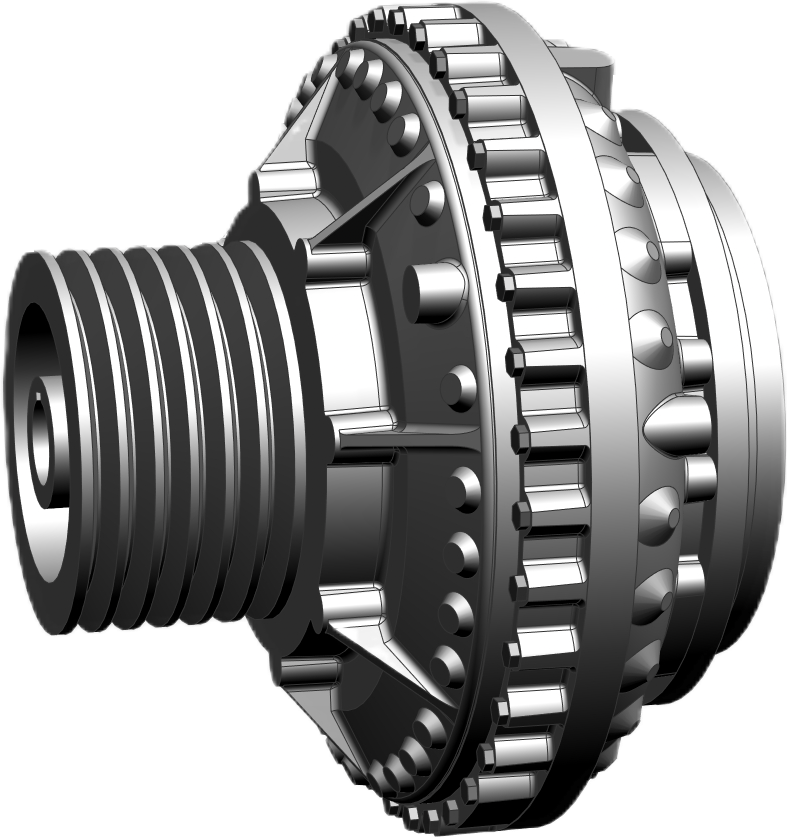

Fluid Couplings excel in providing soft-start capabilities, eliminating sudden jolts during machinery startup. By transmitting power through fluid momentum—where a pump wheel drives a turbine wheel via oil—they absorb shocks and dampen torsional vibrations . This is particularly valuable in heavy-duty applications like conveyor systems or crushers, where abrupt starts can cause mechanical damage. The result? Extended equipment life and reduced downtime.

2. Overload Protection for Motors and Machinery

One of the standout features of Fluid Couplings is their inherent overload protection. When a machine jams or faces excessive load, the coupling allows the motor to continue running without stalling, as the fluid slip limits torque transmission . This prevents motor burnout and avoids costly repairs. For instance, in mining operations, Fluid Couplings protect conveyor belts from overload-induced tears, ensuring uninterrupted production.

3. Energy Efficiency and Load Adaptation

Fluid Couplings enable energy savings by reducing peak current draw during motor startup. They allow motors to start under light load, cutting power consumption and minimizing grid stress . In pump or fan applications, Fluid Couplings facilitate speed adjustment without motor throttling, leading to significant energy conservation—up to 30% in some cases .

4. Low Maintenance and Durability

With no direct mechanical contact between components, Fluid Couplings experience minimal wear. Their simple design—primarily comprising a pump, turbine, and sealed chamber—requires little upkeep beyond periodic oil checks . This reliability translates to lower lifecycle costs, as seen in cement plants where Fluid Couplings operate for years without major overhauls.

5. Versatility Across Industries

From boiler feed pumps in power plants to agitators in chemical processing, Fluid Couplings serve a broad range of applications. They are equally effective in harsh environments, such as underground mining or explosive atmospheres, thanks to their robust construction and compliance with safety standards like ATEX .

---

Real-World Applications

- Mining & Cement: In bucket elevators and grinding mills, Fluid Couplings ensure smooth acceleration under heavy loads, reducing mechanical stress .

- Energy Sector: Turbines and generators use Fluid Couplings to manage variable speeds while isolating vibrations .

- Marine Engineering: Ships employ these couplings for propulsion systems, leveraging their ability to handle high torque without alignment issues .