Hydrodynamic Couplings: A Comprehensive Guide to Proper Usage and Industry Applications

2025-06-04 09:20Hydrodynamic Couplings: A Comprehensive Guide to Proper Usage and Industry Applications

As industrial machinery continues to evolve, hydrodynamic couplings remain a cornerstone of efficient power transmission systems. These devices, also known as fluid couplings, bridge the gap between prime movers and driven equipment, offering unparalleled advantages in load management, vibration damping, and system protection. This article delves into the critical methodologies for operating hydrodynamic couplings across various sectors, supported by technical insights from leading manufacturers and maintenance experts.

I. Fundamentals of Hydrodynamic Couplings

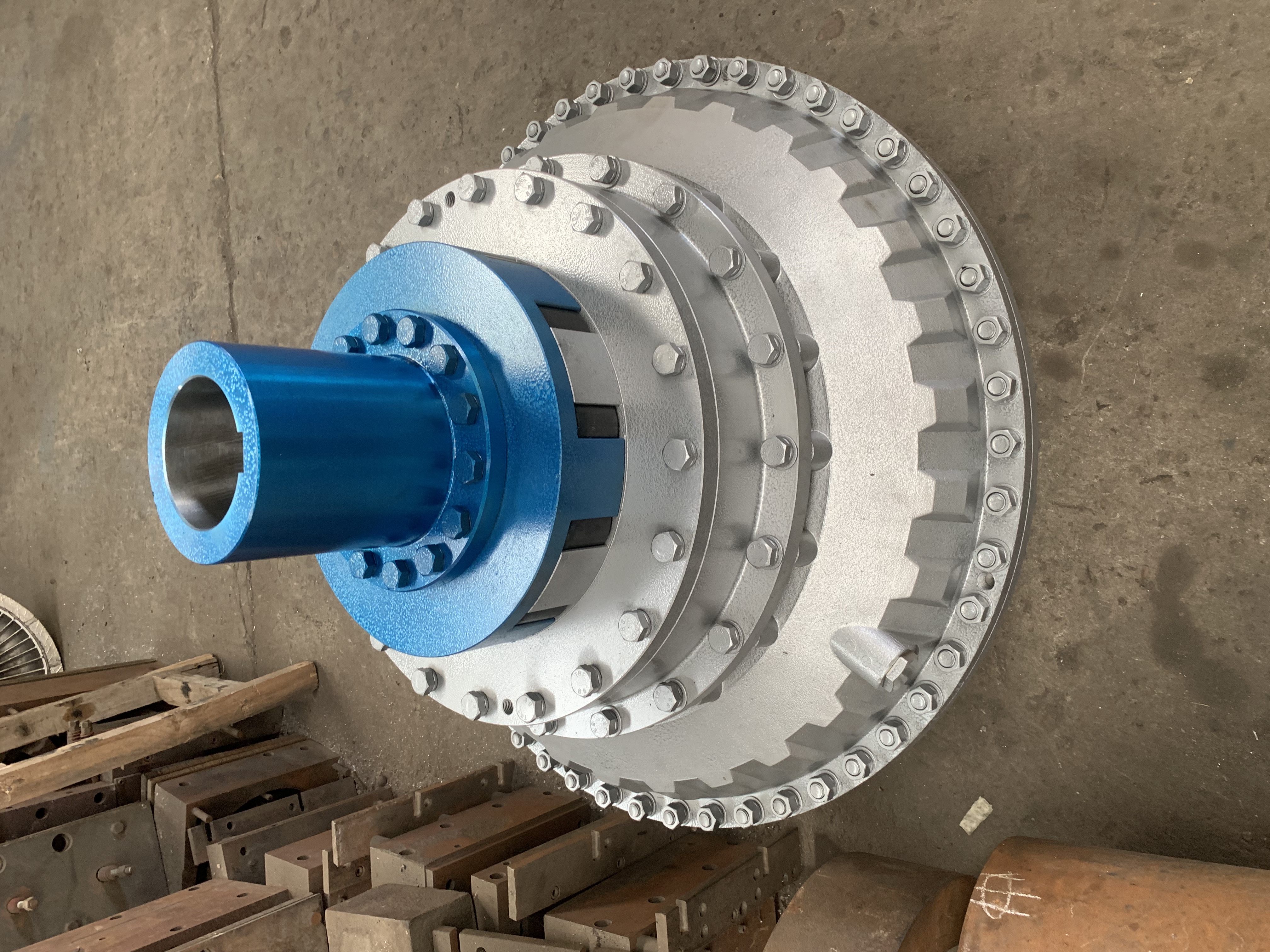

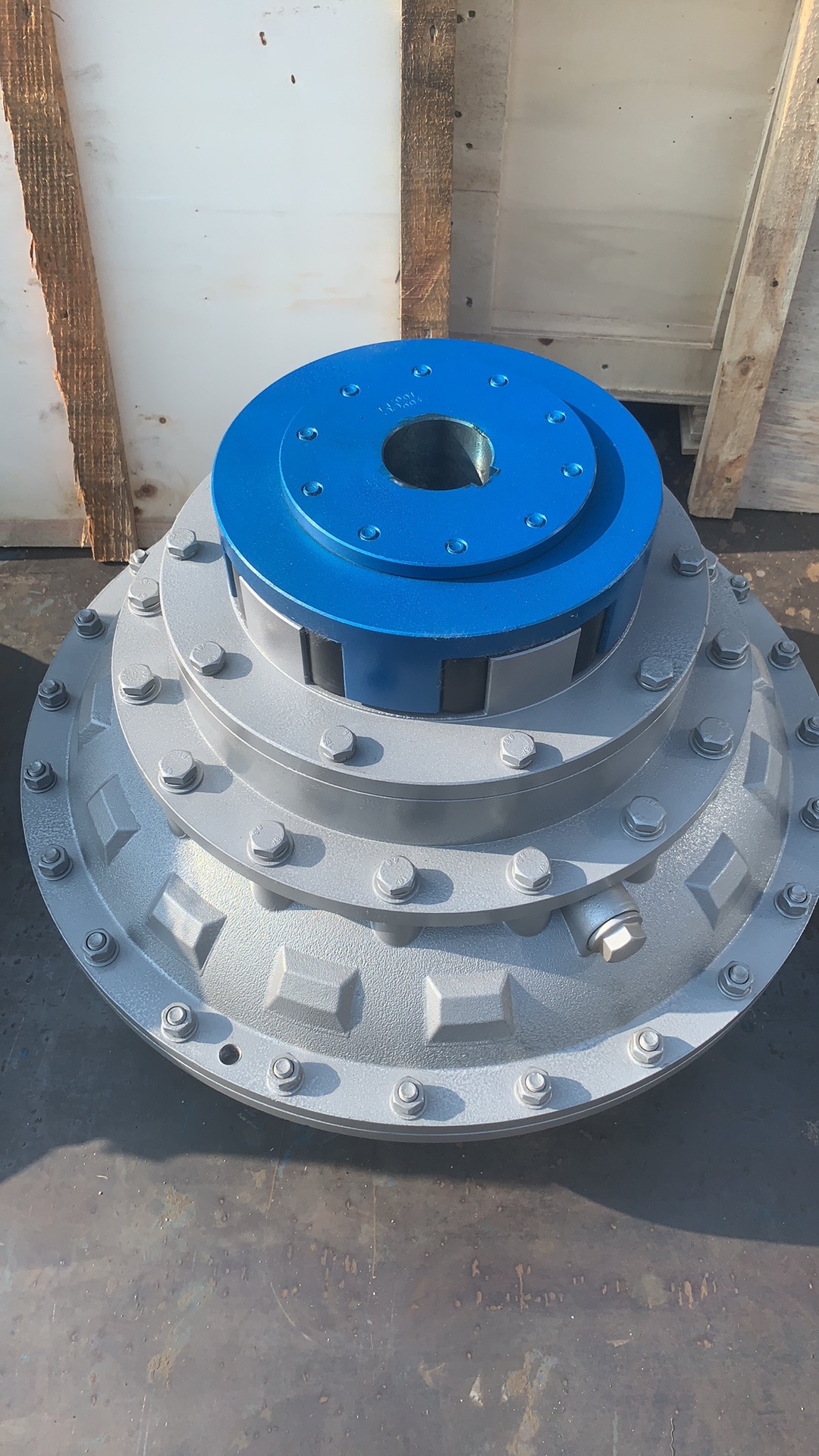

Hydrodynamic couplings operate on the principle of fluid dynamics, transmitting torque through the kinetic energy of a working fluid—typically oil or water-based solutions. The core components include:

Pump Wheel: Connected to the input shaft, it accelerates the fluid.

Turbine Wheel: Receives energy from the fluid, driving the output shaft.

Shell: Seals the assembly while allowing controlled heat dissipation.

Unlike rigid couplings, hydrodynamic couplings eliminate direct metal-to-metal contact, making them ideal for applications requiring smooth starts and overload protection. Recent innovations, such as the non-destructive disassembly tools developed for mining equipment (as reported by industry leaders in 2025), have reduced maintenance downtime by 600%, underscoring their growing importance in heavy industries .

II. Operational Best Practices

1. Fluid Selection and Charging Procedures

The performance of hydrodynamic couplings hinges on proper fluid management:

Fluid Types:

Mineral-based oils (e.g., ISO VG 32) for general industrial use.

Synthetic fluids for high-temperature environments (e.g., foundries).

Water-glycol mixtures in explosion-prone areas like coal mines.

Charging Protocol:

Clean the oil reservoir thoroughly to prevent contamination.

Fill 40–80% of the coupling’s capacity, depending on torque requirements. Overfilling increases startup torque but risks overheating.

For multi-motor systems (e.g., conveyor belts), ensure identical fluid volumes across all couplings to balance load distribution.

2. Alignment and Installation

Precision alignment is non-negotiable:

Maintain shaft misalignment below 0.3 mm for elastomeric-coupled systems.

Use laser alignment tools to achieve ≤0.1 mm accuracy in critical applications like turbine generators.

Avoid hammering during installation; specialized extraction bolts preserve seal integrity.

3. Startup and Load Management

Gradually ramp up speed to allow fluid circulation.

Monitor current draw during motor startup; deviations >5% between parallel drives indicate uneven fluid charging.

Limit consecutive restarts: ≤5 attempts for no-load conditions, ≤3 under load, with 2-minute cooling intervals.

III. Maintenance Strategies for Peak Performance

1. Routine Inspections

Daily:

Check for oil leaks at seals and gaskets.

Clean external surfaces to prevent heat retention.

Monthly:

Verify fluid levels using marked inspection ports.

Test fluid viscosity and contamination with portable analyzers.

2. Overhaul Cycles

Replace seals every 3,000 operating hours or when leakage exceeds 5 mL/day.

Conduct full fluid replacement annually, prioritizing systems in dusty environments.

For mining equipment, adopt predictive maintenance using vibration sensors to detect impeller imbalance early.

3. Temperature Control

Operating range: -20°C to +90°C. Install auxiliary coolers if ambient temperatures exceed 35°C.

Never operate couplings with fluid temperatures >110°C—this degrades seals and reduces dielectric strength.

IV. Sector-Specific Applications

1. Mining & Material Handling

Hydrodynamic couplings dominate conveyor and crusher drives due to their ability to:

Absorb shock loads from uneven material feed.

Prevent motor burnout during jammed conditions via fluid slippage.

Case Study: A Western Australian iron ore mine reduced belt drive failures by 42% after standardizing on hydrodynamic couplings with automated fluid monitoring.

2. Automotive & Transportation

Though largely replaced by electronic clutches in modern vehicles, hydrodynamic couplings still excel in:

Heavy-duty transmissions for mining trucks.

Marine propulsion systems, where they dampen engine torsional vibrations.

3. HVAC & Pump Systems

Water-Cooled Chillers: Couplings isolate compressor vibrations, reducing noise to <65 dB(A).

Fire Pumps: Ensure smooth engagement during emergency startups.

V. Emerging Trends and Innovations

The hydrodynamic coupling market is witnessing transformative advancements:

Smart Couplings: IoT-enabled units transmitting real-time data on fluid health and torque efficiency.

Eco-Friendly Fluids: Biodegradable oils meeting ISO 15380 standards, cutting hazardous waste by 70%.

Additive Manufacturing: 3D-printed titanium impellers reducing weight by 40% while maintaining strength.

Conclusion

Mastering hydrodynamic couplings requires a blend of mechanical knowledge and disciplined maintenance. By adhering to standardized charging protocols, implementing predictive upkeep, and leveraging new technologies, industries can unlock decades of reliable service from these versatile power transmission devices. As the sector evolves, continuous education on hydrodynamic coupling advancements remains key to operational excellence.