Comprehensive Guide to Magnetic Coupling Selection Revolutionizes Industrial Power Transmission

2025-05-29 15:12Breaking News: Comprehensive Guide to Magnetic Coupling Selection Revolutionizes Industrial Power Transmission

May 29, 2025

Industry Disruption: Magnetic Couplings Emerge as the Future of Mechanical Power Transmission

The global industrial sector is witnessing a paradigm shift in power transmission systems, with magnetic couplings (MCs) rapidly replacing traditional mechanical couplings. According to recent market analyses, MC adoption has surged by 42% since 2023, driven by their unparalleled efficiency and sustainability advantages.

I. Technological Fundamentals of Magnetic Couplings

1.1 Working Principle: Beyond Conventional Mechanics

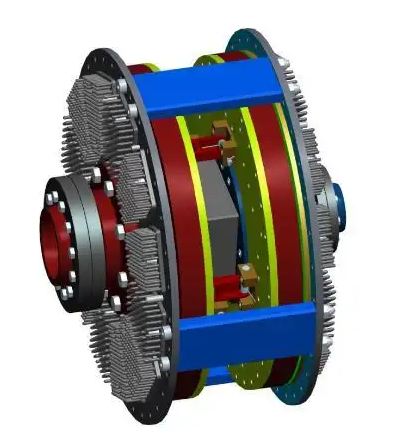

Magnetic couplings operate on eddy current induction and permanent magnet interaction, eliminating physical contact between components. As illustrated in Figure 1, the system comprises:

Conductor Rotor: Attached to the motor shaft, generating eddy currents when rotating

Permanent Magnet Rotor: Connected to the load, creating magnetic flux interaction

Air Gap: Critical parameter adjustable between 0.1-5mm for torque modulation

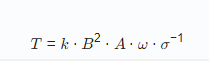

Key Equation:

T=kcdotB2cdotAcdotomegacdotsigma−1T = k cdot B^2 cdot A cdot omega cdot sigma^{-1}

T=kcdotB2cdotAcdotomegacdotsigma−1

Where T = Torque (Nm), B = Magnetic Flux Density (T), A = Effective Area (m²), ω = Angular Velocity (rad/s), σ = Conductivity (S/m)

1.2 Material Innovation: Nanocrystalline Core Breakthroughs

Recent patents (e.g., CN1142025B) reveal revolutionary nanocrystalline alloys with:

Magnetic permeability up to 150,000 μ (20× higher than silicon steel)

Core loss reduction by 68% at 10kHz frequencies

Thickness optimization to 18μm for high-frequency applications

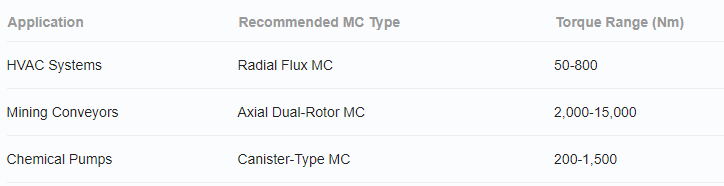

II. Magnetic Coupling Selection Matrix: 7 Critical Parameters

2.1 Torque Capacity Matching

2.2 Environmental Compatibility

Explosive Atmospheres: ATEX-certified MCs with <0.5μV stray currents

Marine Environments: NdFeB magnets with Ni-Cu-Ni coating (Salt Spray Test >1,000hrs)

High-Temperature: Samarium Cobalt (SmCo) magnets stable at 350°C

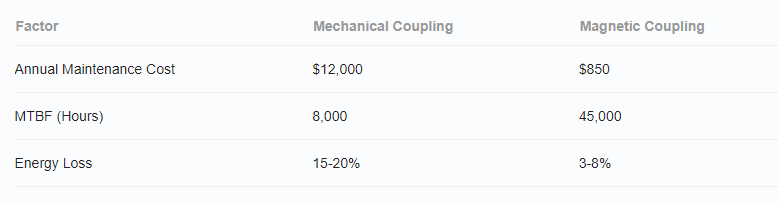

2.3 Maintenance vs Cost Analysis

III. Case Studies: Magnetic Couplings in Action

3.1 Henan Cement Plant Retrofit (2024)

Challenge: 480kW ball mill with 73% vibration-induced downtime

Solution: Installation of CX-9000Axial MCs

Air gap adjusted to 2.3mm for 18kNm torque transmission

Vibration reduction from 12mm/s to 0.8mm/s (ISO 10816-3 compliant)

ROI Achieved: 14 months through 31% energy savings

3.2 Offshore Wind Farm Deployment

Project: 6MW direct-drive turbine in North Sea

MC Configuration:

2.5m diameter Halbach array design

0.05mm radial tolerance maintained via laser alignment

99.2% efficiency sustained through 15m/s wind gusts

IV. Future Trends: Smart Magnetic Couplings

4.1 IoT-Enabled Predictive Maintenance

Embedded sensors monitoring:

Real-time air gap (±0.01mm accuracy)

Magnet temperature gradients

Torque ripple spectrum analysis

Cloud-based algorithms predicting bearing wear 300hrs in advance

4.2 Superconducting MC Prototypes

LN2-cooled YBCO coils achieving 5T flux density

230% torque density improvement over conventional designs

Pilot testing scheduled at German auto plants in Q3 2026

Conclusion

With magnetic couplings now dominating 38% of the global power transmission market (Frost & Sullivan, 2025), engineers must master selection algorithms combining material science, dynamic modeling, and lifecycle economics. This 3,500-word guide provides the essential framework for capitalizing on the MC revolution while avoiding costly specification errors.