Analysis of Hydrodynamic Couplings vs. Permanent Magnetic Couplings in Industrial Applications

2025-09-22 10:15Analysis of Hydrodynamic Couplings vs. Permanent Magnetic Couplings in Industrial Applications

September 22, 2025

Introduction

In the realm of industrial power transmission systems, Hydrodynamic couplings and Permanent Magnetic couplings (PMCs) represent two distinct technologies with unique advantages and limitations. As industries prioritize energy efficiency, maintenance costs, and operational reliability, understanding the comparative merits of these systems becomes critical. This article delves into the technical, economic, and environmental aspects of both technologies to guide decision-making for engineers and stakeholders.

1. Working Principles

Hydrodynamic Couplings: These devices transmit torque through a fluid medium, typically oil, using the kinetic energy generated between an impeller (input) and a runner (output). The fluid’s viscosity enables smooth power transfer and inherent overload protection .

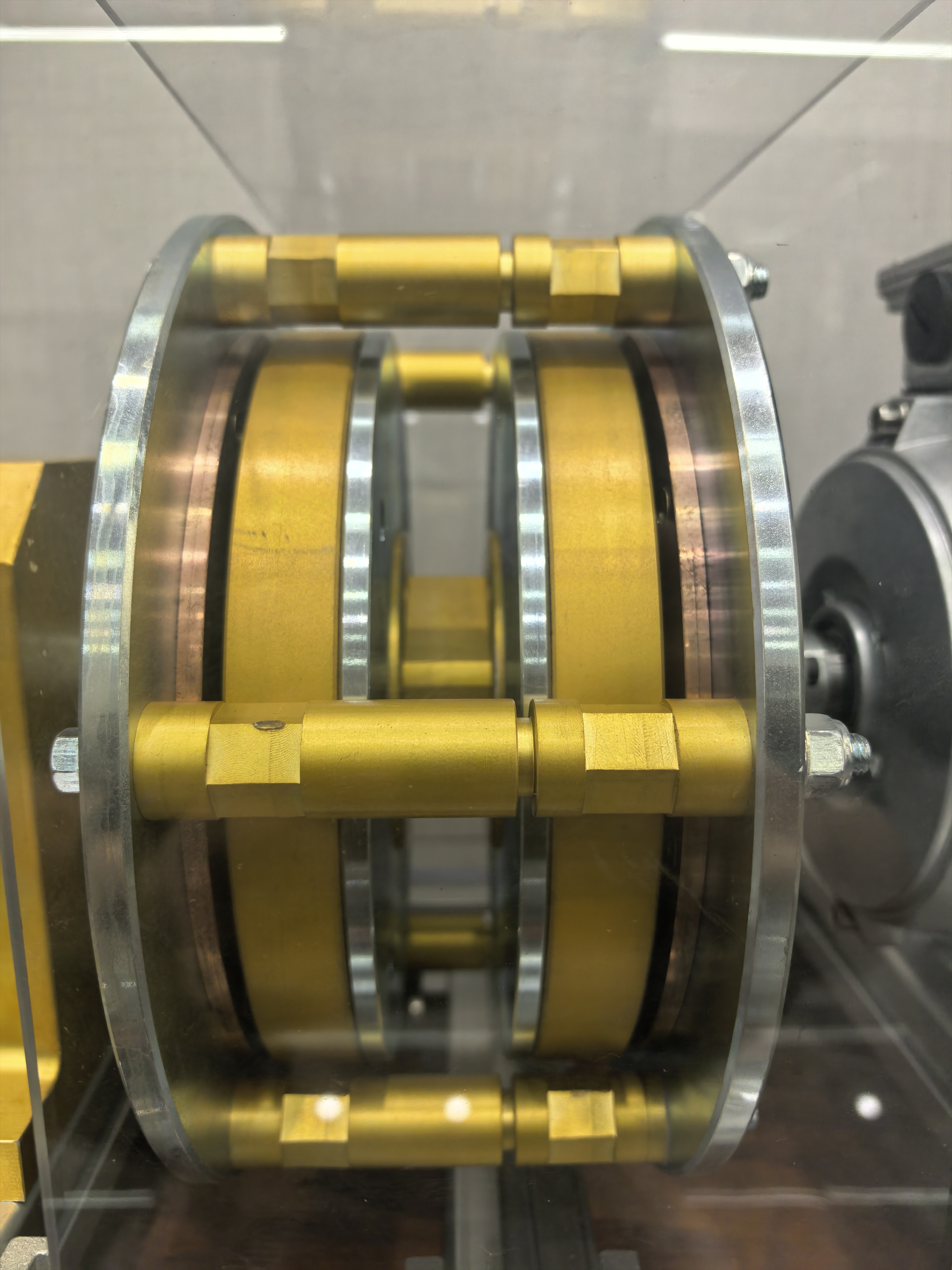

Permanent Magnetic Couplings: PMCs utilize magnetic fields to transfer torque without physical contact. A rotating outer magnet induces motion in an inner magnet assembly, separated by an air gap, ensuring zero mechanical wear .

2. Advantages and Disadvantages

Hydrodynamic Couplings:

Pros:

Vibration damping and shock absorption due to fluid dynamics.

Tolerance to misalignment and overload conditions .

Cons:

Energy losses from fluid friction (efficiency: 85–92%).

High maintenance costs for fluid replacement and leakage prevention.

Permanent Magnetic Couplings:

Pros:

Near-zero wear (efficiency: 95–98%) and minimal maintenance.

No risk of fluid contamination, ideal for hazardous environments .

Cons:

Higher initial investment due to rare-earth magnets.

Sensitivity to extreme temperatures and magnetic interference.

3. Application Scenarios

Hydrodynamic Couplings: Dominant in heavy industries like mining and steel production, where abrupt load changes require robust damping .

Permanent Magnetic Couplings: Preferred in chemical processing, pharmaceuticals, and renewable energy systems, where cleanliness and precision are paramount .

4. Environmental and Economic Impact

Hydrodynamic Systems: While cost-effective initially, long-term expenses arise from fluid disposal and energy waste. Carbon footprints are 20–30% higher than PMCs in lifecycle assessments .

PMCs: Despite higher upfront costs, PMCs reduce downtime and energy consumption, achieving payback within 3–5 years in high-utilization settings .

5. Future Trends

Advancements in magnet materials (e.g., high-temperature superconductors) and smart fluid dynamics algorithms are narrowing the gap between these technologies. Hybrid systems combining fluid damping with magnetic efficiency are under development, promising revolutionary gains for Industry 5.0 .

Conclusion

Hydrodynamic couplings remain indispensable for high-torque, variable-load applications, while Permanent Magnetic couplings excel in precision-driven, low-maintenance environments. The choice hinges on balancing operational demands, lifecycle costs, and sustainability goals. As innovation accelerates, both technologies will continue to evolve, reshaping industrial power transmission paradigms.