Fluid Coupling Selection Guide

2025-06-24 16:17Fluid Coupling Selection Guide

1. Introduction to Fluid Couplings

A Fluid Coupling is a hydrodynamic device that transmits rotational power between shafts using hydraulic fluid. Widely used in industrial machinery, mining equipment, and power generation systems, it offers smooth torque transmission, overload protection, and vibration damping. This guide provides a systematic approach to selecting the optimal Fluid Coupling for your application.

2. Core Selection Principles

2.1 Power Matching

The Fluid Coupling’s rated power must align with the prime mover (e.g., motor) and driven equipment.

Rule: Select a coupling with 10–15% higher power capacity than the prime mover’s maximum output ().

Risk: Undersized couplings risk overheating and failure; oversized units increase costs and reduce efficiency.

2.2 Speed Compatibility

Match the input/output speeds to ensure optimal performance:

Verify the prime mover’s rated speed (e.g., 1,500 RPM) and driven equipment requirements ().

Use speed-torque curves to avoid resonance zones.

2.3 Environmental Factors

Temperature: High-temperature environments (e.g., steel mills) require couplings with heat-resistant seals.

Dust/Moisture: For coal mines or chemical plants, choose explosion-proof or corrosion-resistant models ().

2.4 Load Characteristics

Constant Loads (e.g., conveyors): Standard Fluid Couplings suffice.

Variable/Shock Loads (e.g., crushers): Opt for torque-limiting or variable-fill designs ().

3. Types of Fluid Couplings

3.1 Constant-Fill (Standard) Fluid Couplings

Features: Simple design, fixed fluid volume, high efficiency (up to 97%).

Applications: Pumps, fans, and low-shock systems ().

Limitation: Poor overload protection; unsuitable for high-inertia starts.

3.2 Torque-Limiting Fluid Couplings

Design: Restricts torque spikes during stalling or overloads (overload coefficient: 2–2.7) ().

Use Case: Ball mills, crushers, and heavy machinery requiring surge protection.

3.3 Variable-Speed Fluid Couplings

Operation: Adjusts output speed by varying fluid volume via external pumps or scoops ().

Advantages: Energy savings in variable-speed applications (e.g., HVAC systems).

Subtypes:

Inlet-Control: Adjusts fluid inflow (e.g., YOP200 series) ().

Outlet-Control: Regulates outflow for precision speed tuning.

4. Technical Parameters & Calculations

4.1 Key Specifications

Overload Coefficient: Critical for shock loads. YOP320 couplings offer 2–2.7 overload capacity ().

Input/Output Speed: Ensure alignment with prime mover and driven equipment.

Dimensions: Check shaft diameters (e.g., YOP200 supports 60mm max input length) ().

4.2 Sizing Formulas

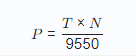

Power Transmission:

P=fracTtimesN9550P = frac{T times N}{9550}

P=fracTtimesN9550

Where ( P ) = power (kW), ( T ) = torque (Nm), ( N ) = speed (RPM).

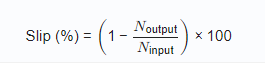

Slip Calculation:

text{Slip (%)} = left(1 - frac{N_{text{output}}}{N_{text{input}}}right) times 100

5. Application-Specific Guidelines

5.1 Fans & Blowers

Requirements: Smooth acceleration, moderate overload protection.

Recommended: YOP320 with 1,500 RPM input and 110mm shaft compatibility ().

5.2 Mining & Heavy Machinery

Challenges: High inertia, dust exposure.

Solution: Torque-limiting couplings with explosion-proof certification ().

5.3 HVAC Systems

Focus: Energy efficiency via variable-speed control.

Fit: Outlet-control Fluid Couplings with external cooling systems ().

6. Maintenance & Troubleshooting

Fluid Checks: Monitor viscosity and contamination levels quarterly.

Seal Inspections: Replace worn seals to prevent leaks in humid environments.

Overheating Causes:

Overfilling/underfilling of fluid.

Misalignment exceeding 0.1mm/m.

7. Vendor Evaluation Tips

Certifications: Prioritize ISO 9001-compliant manufacturers.

Testing Data: Request performance curves and overload test reports.

Case Studies: Review success stories in similar industries (e.g., Zhongxing Fluid Coupling’s YOP series) (, ).

8. Conclusion

Selecting the right Fluid Coupling demands a balance of power, speed, environmental resilience, and load dynamics. By leveraging torque-limiting designs for heavy machinery, variable-speed models for energy efficiency, and robust materials for harsh conditions, engineers can optimize equipment longevity and performance. Always validate choices against manufacturer data and real-world application benchmarks.