Introduction to Magnetic Couplings: Selection and Application

2025-09-09 15:38Introduction to Magnetic Couplings: Selection and Application

September 9, 2025

1. Fundamental Principles of Magnetic Couplings

Magnetic couplings transmit torque through non-contact magnetic fields, eliminating mechanical wear and enabling hermetic sealing. Key mechanisms include:

Flux Transfer: Permanent magnets (e.g., NdFeB) generate synchronous or asynchronous torque across an air gap (0.5–5 mm), isolating driven equipment from motor vibrations.

Hermetic Separation: Critical for hazardous environments (e.g., chemical processing), preventing fluid leakage via static seals.

Energy Efficiency: Achieves >98% torque transmission efficiency by minimizing eddy current losses through laminated shields .

2. Selection Criteria for Industrial Applications

Torque Capacity

Standard Range: 10 N·m to 15,000 N·m.

High-Torque Solutions: Asynchronous couplings tolerate misalignment in heavy machinery (e.g., ball mills, crushers) .

Environmental Compatibility

Temperature Resilience: Operates from -40°C to 220°C with ceramic coatings.

Corrosion Resistance: Stainless steel or polymer housings for marine/chemical sectors.

Safety and Compliance

ATEX/IECEx Certification: Mandatory for explosive atmospheres.

FDA-Grade Materials: Essential for pharmaceutical and food processing .

3. Technical Innovations Driving Performance

Eddy Current Mitigation: Segmented magnets and copper shielding reduce losses by 20–35% .

Smart Monitoring: IoT sensors track real-time torque, temperature, and alignment via embedded diagnostics.

Modular Design: Enables rapid customization for pumps, compressors, and HVAC systems.

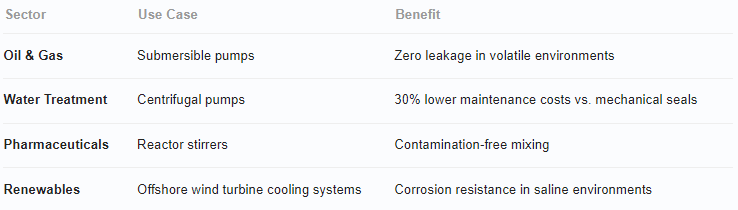

4. Industry-Specific Applications

5. Overcoming Common Challenges

Axial Force Management: Integrated thrust bearings absorb displacement forces.

Cost Optimization: Automated manufacturing cuts unit costs by 18% for bulk orders .

Retrofitting Legacy Systems: Adapter kits enable seamless integration with existing machinery.

6. Future Trends

Hybrid Materials: Graphene-enhanced magnets for higher flux density (1.5 T).

Circular Economy: Recyclable rare-earth magnets reducing environmental footprint.

AI-Driven Predictive Maintenance: Algorithms forecasting coupling failures 48+ hours in advance.

Conclusion

Magnetic couplings offer transformative advantages in safety, efficiency, and reliability across industries. By aligning selection parameters with operational demands—from torque requirements to environmental constraints—engineers can harness their full potential for next-generation applications.