Dalian Mairuisheng Showcases Advanced Custom Capabilities in Specialized Fluid Coupling Designs for Enhanced Safety and Performance

2026-01-28 08:31Dalian Mairuisheng Showcases Advanced Custom Capabilities in Specialized Fluid Coupling Designs for Enhanced Safety and Performance

DALIAN, China – January 26, 2026 – Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd., a prominent force in China’s industrial transmission sector, today unveiled its advanced engineering capabilities in producing highly customized, application-specific fluid couplings. The company, leveraging its deep-rooted expertise in serving the stringent demands of domestic mining and heavy industry, has perfected the design and manufacture of complex variants, including the Fluid Coupling with Brake Disc, the Fluid Coupling with pulley, and specialized Hydrodynamic Coupling with Double Fluid Units and Hydrodynamic Coupling with enlarged delayed filling chamber systems. These designs directly address critical challenges in machine safety, space constraints, and controlled torque management for global industrial clients.

Moving beyond standard catalogue offerings, Dalian Mairuisheng’s focus on integrated design solutions allows original equipment manufacturers (OEMs) and end-users to streamline their drive train layouts, enhance operational safety, and achieve precise motor load management. This announcement underscores the company's commitment to acting as a collaborative engineering partner capable of delivering not just components, but optimized mechanical systems.

1. Integrated Safety and Space-Saving Solutions: Brake Disc and Pulley Variants

A core strength of Dalian Mairuisheng’s customization lies in the integration of auxiliary functions directly onto the coupling housing, eliminating the need for separate components and saving valuable installation space.

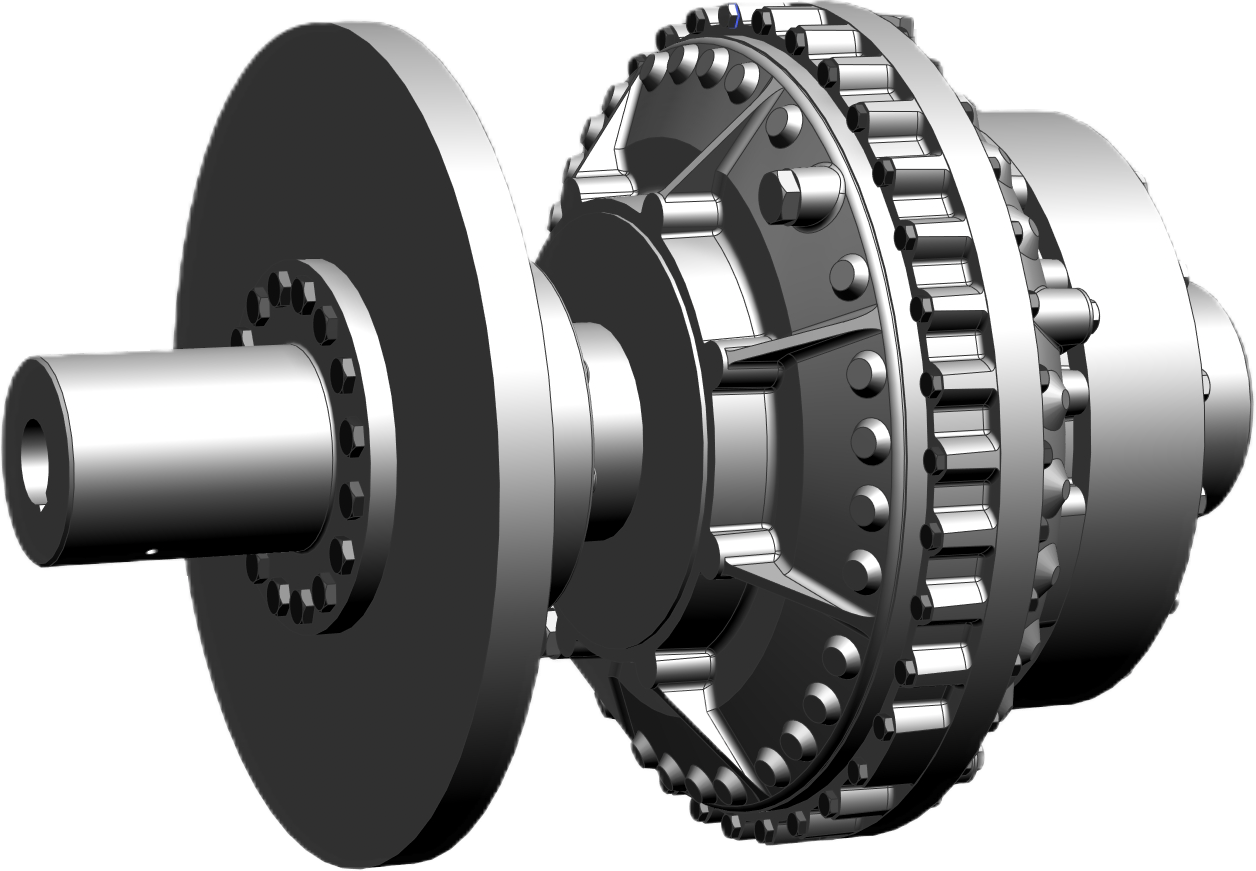

Fluid Coupling with Brake Disc: This design incorporates a high-quality, machined brake disc directly onto the coupling's output or input side. It is engineered for applications where fail-safe braking or precise stopping is paramount, such as in inclined conveyors, heavy-duty winches, or test bench applications. The integrated design ensures perfect concentricity and rigidity, leading to smoother braking performance and reduced wear compared to separately mounted disc systems. This Fluid Coupling with Brake Disc provides a compact, reliable, and factory-aligned safety solution.

Fluid Coupling with pulley (Brake Wheel): In many conveyor and lifting applications, the need for a brake is coupled with the requirement for a V-groove pulley or a flat crown pulley for belt driving. Dalian Mairuisheng’s expertise allows the fabrication of a coupling where the external housing is precisely machined to function as this crucial pulley or a dedicated brake drum. This Fluid Coupling with pulley variant is a testament to the company’s ability to create multi-functional units that simplify the entire drive assembly, reduce component count, and enhance overall system reliability by ensuring perfect alignment between the coupling, the driving pulley, and the braking surface.

2. Advanced Torque Management: Dual and Extended Chamber Engineering

For applications requiring exceptional control over the starting torque curve and acceleration characteristics, Dalian Mairuisheng offers sophisticated internal fluid circuit modifications.

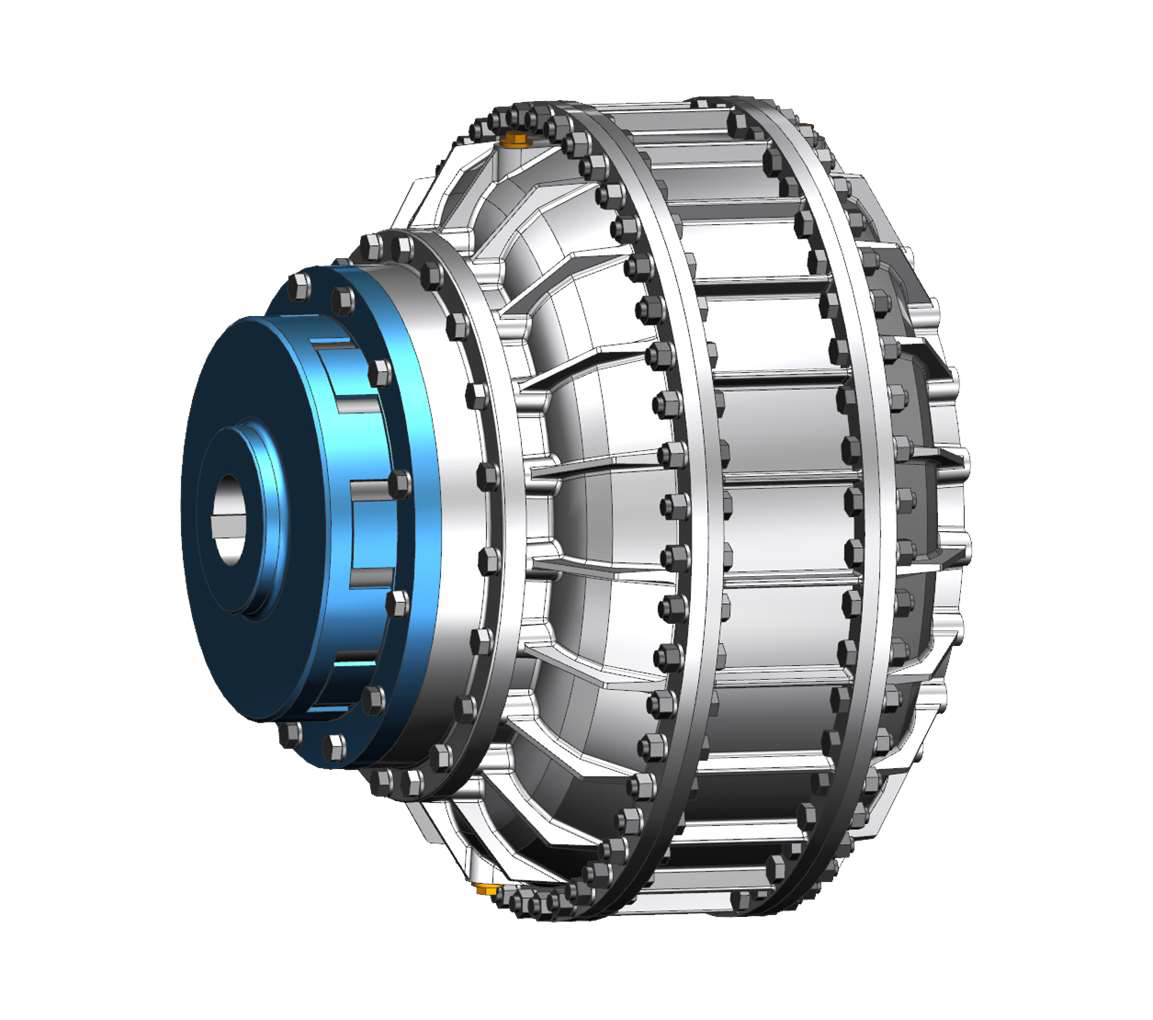

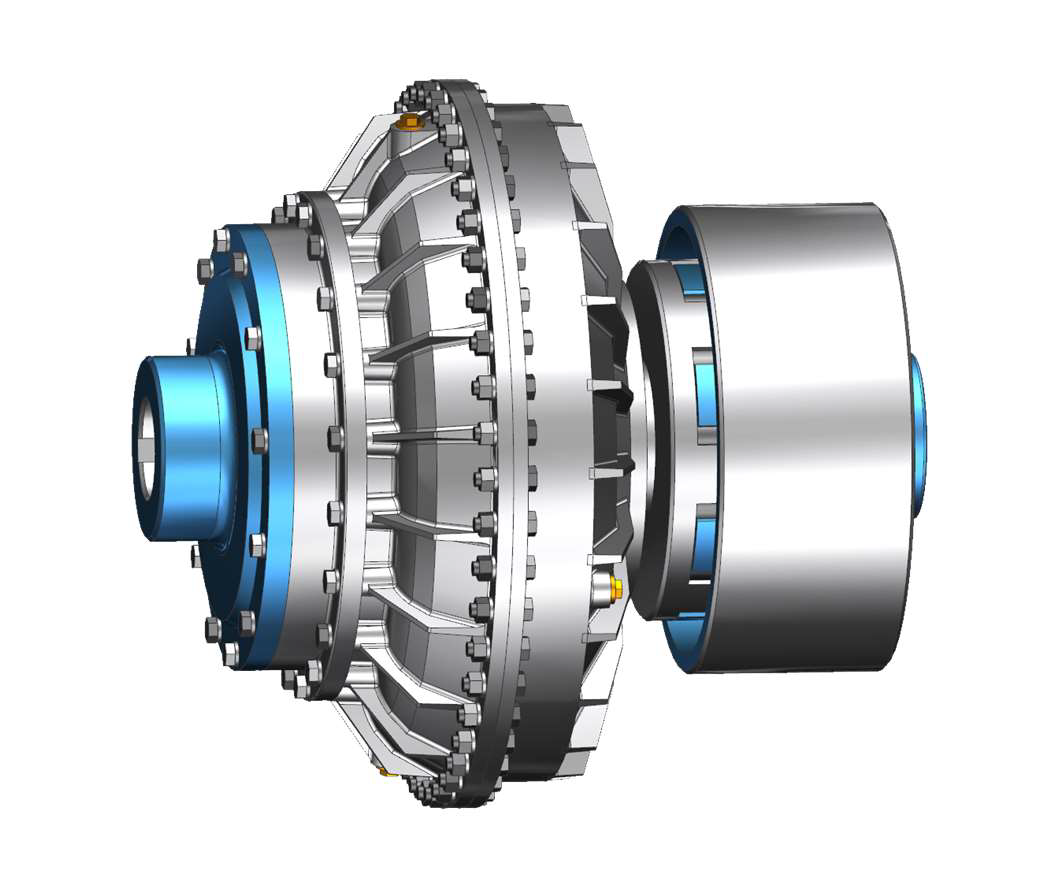

Hydrodynamic Coupling with Double Fluid Units (Dual Chamber): This advanced configuration features two separate fluid working circuits or chambers. It is specifically engineered for driving extremely high-inertia loads, such as large ball mills, crushers, or main fans. The Hydrodynamic Coupling with Double Fluid Units provides a uniquely shaped torque curve, often characterized by a pronounced "hump" that delivers very high breakaway torque to initiate movement, which then smoothly transitions to a lower torque for steady-state operation. This protects the motor from prolonged high-current draw and gently accelerates the massive load, significantly reducing mechanical stress on gears, belts, and the driven equipment.

Hydrodynamic Coupling with enlarged delayed filling chamber: Building upon the principle of controlled acceleration, this design focuses on refining the fill cycle of the secondary chamber. By strategically enlarging the delayed filling (or auxiliary) chamber and calibrating the fluid transfer orifices, engineers can precisely dictate how torque ramps up during the start sequence. The Hydrodynamic Coupling with enlarged delayed filling chamber is ideal for applications like long, overland conveyors or mixed-load scenarios where an even smoother, more elongated acceleration profile is needed to prevent belt slippage, material spillage, or dynamic tension issues. It represents a nuanced approach to tailoring the startup behavior to the exact kinematics of the driven system.

3. From Specification to Solution: A Collaborative Engineering Case

The value of these specialized couplings is best illustrated through a real-world engineering dialogue. A recent collaboration with a Chinese mining equipment OEM serves as a prime example. The client’s initial specification for a new conveyor drive system called for a standard Fluid Coupling with Brake Disc alongside a separate gearbox and pulley assembly. The Dalian Mairuisheng engineering team, upon reviewing the spatial layout and functional requirements, proposed a more integrated and cost-effective solution: a single Fluid Coupling with pulley, where the housing was machined to serve as both the brake drum and the core drive pulley.

This consolidated design eliminated two sets of couplings, mountings, and alignment procedures. The result was a 15% reduction in the drive package's footprint, a significant decrease in installation time and complexity, and an improvement in overall torsional stiffness. This case underscores Dalian Mairuisheng’s philosophy: to apply its mastery over Fluid Coupling with Brake Disc and Fluid Coupling with pulley technologies not just to manufacture to print, but to innovate for added value, optimizing the entire drive train for performance, reliability, and total cost of ownership.

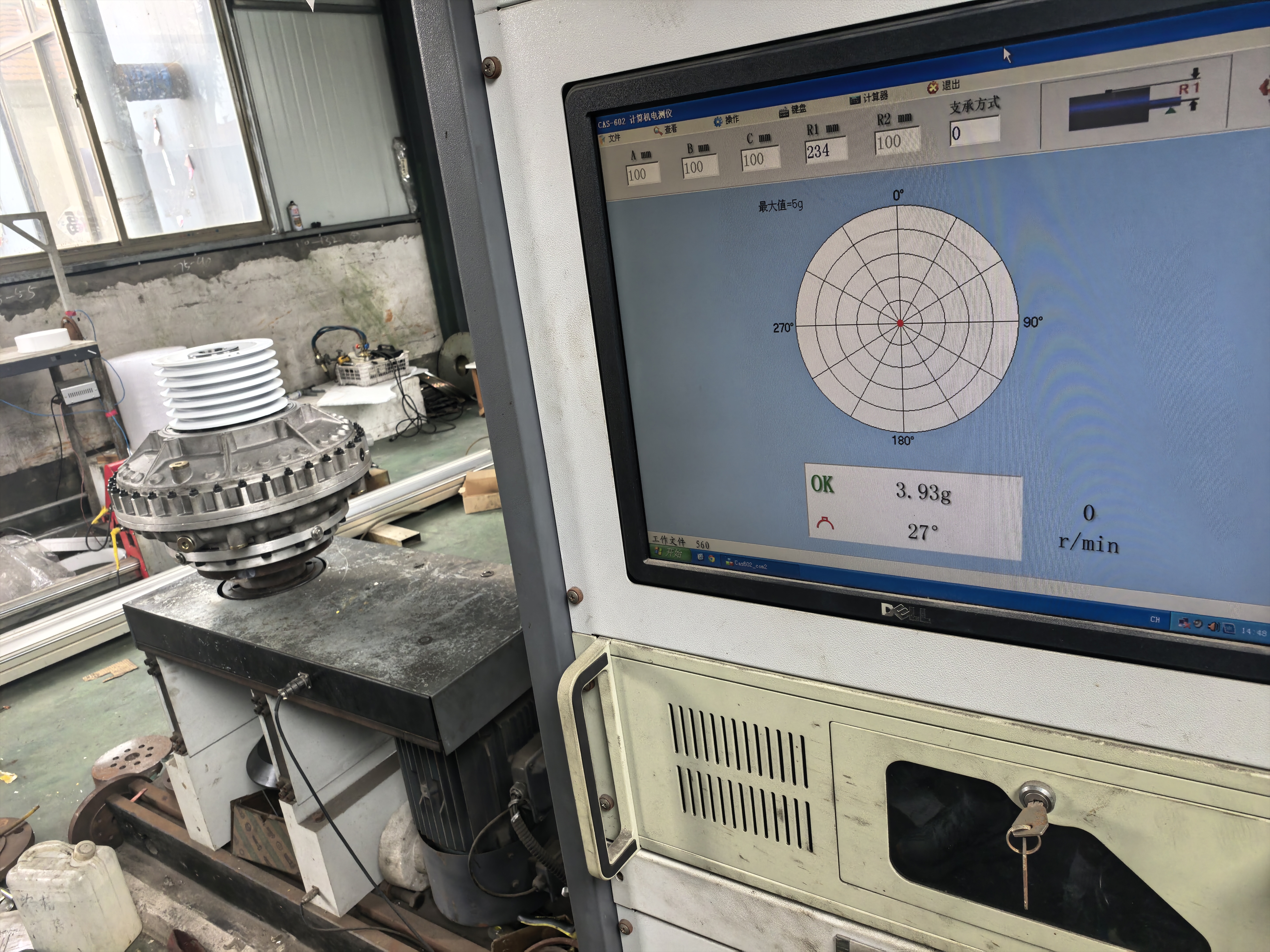

4. A Foundation of Manufacturing Excellence

These complex customizations are made possible by the company’s vertically integrated manufacturing facilities in Dalian, which encompass precision casting, CNC machining, dynamic balancing, and full-load testing. "The ability to reliably produce a robust Hydrodynamic Coupling with Double Fluid Units or a precisely calibrated Hydrodynamic Coupling with enlarged delayed filling chamber stems from our control over the entire production process," states the Chief Production Engineer. "From the metallurgy of the castings to the micron-level tolerances in the chamber machining, every step is geared towards achieving the exact performance characteristics our clients' applications demand."

5. Engaging with Global Markets

As Dalian Mairuisheng looks to expand its international presence, it positions these specialized capabilities as a key differentiator. "The global market for standard fluid couplings is well-served. Where we bring exceptional value is in solving complex drive train challenges with engineered solutions," says the Director of International Business Development. "Whether a client requires the integrated safety of a Fluid Coupling with Brake Disc, the space-saving efficiency of a Fluid Coupling with pulley, or the refined load management of a Hydrodynamic Coupling with Double Fluid Units or an enlarged delayed filling chamber, we have the proven experience and technical depth to deliver. We invite engineers and procurement specialists worldwide to present us with their most demanding applications."

About Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd.

Dalian Mairuisheng is a leading Chinese manufacturer specializing in the design and production of fluid couplings and related power transmission components. With a strong foundation in serving China's mining, port, cement, and metallurgy industries, the company is renowned for its reliability, extensive product range from small to large models, and its superior capability in customizing and special-purpose coupling designs. Its expertise in integrated and complex variants like those highlighted above demonstrates its commitment to advanced engineering and practical innovation for heavy industry.