Comprehensive Guide to Permanent Magnetic Coupling Selection

2025-06-10 08:52Comprehensive Guide to Permanent Magnetic Coupling Selection: Innovations and Industry Best Practices

June 10, 2025

Revolutionizing Industrial Efficiency: The Rise of Permanent Magnetic Couplings

In an era dominated by energy transition and industrial automation, Permanent Magnetic Couplings (PMCs) have emerged as a cornerstone technology for torque transmission systems. Recent advancements, including patents from industry giants like Sinopec Oilfield Service Corporation and breakthrough designs from Jiangsu University, are reshaping how industries select and deploy PMCs. This press release delves into the latest innovations, selection criteria, and sector-specific applications to empower engineers and decision-makers.

1. Core Principles of Permanent Magnetic Couplings

PMCs transmit torque through magnetic fields without physical contact, eliminating wear and reducing maintenance costs. Key components include:

Permanent Magnets: Typically neodymium-based, arranged to generate a high-intensity magnetic field.

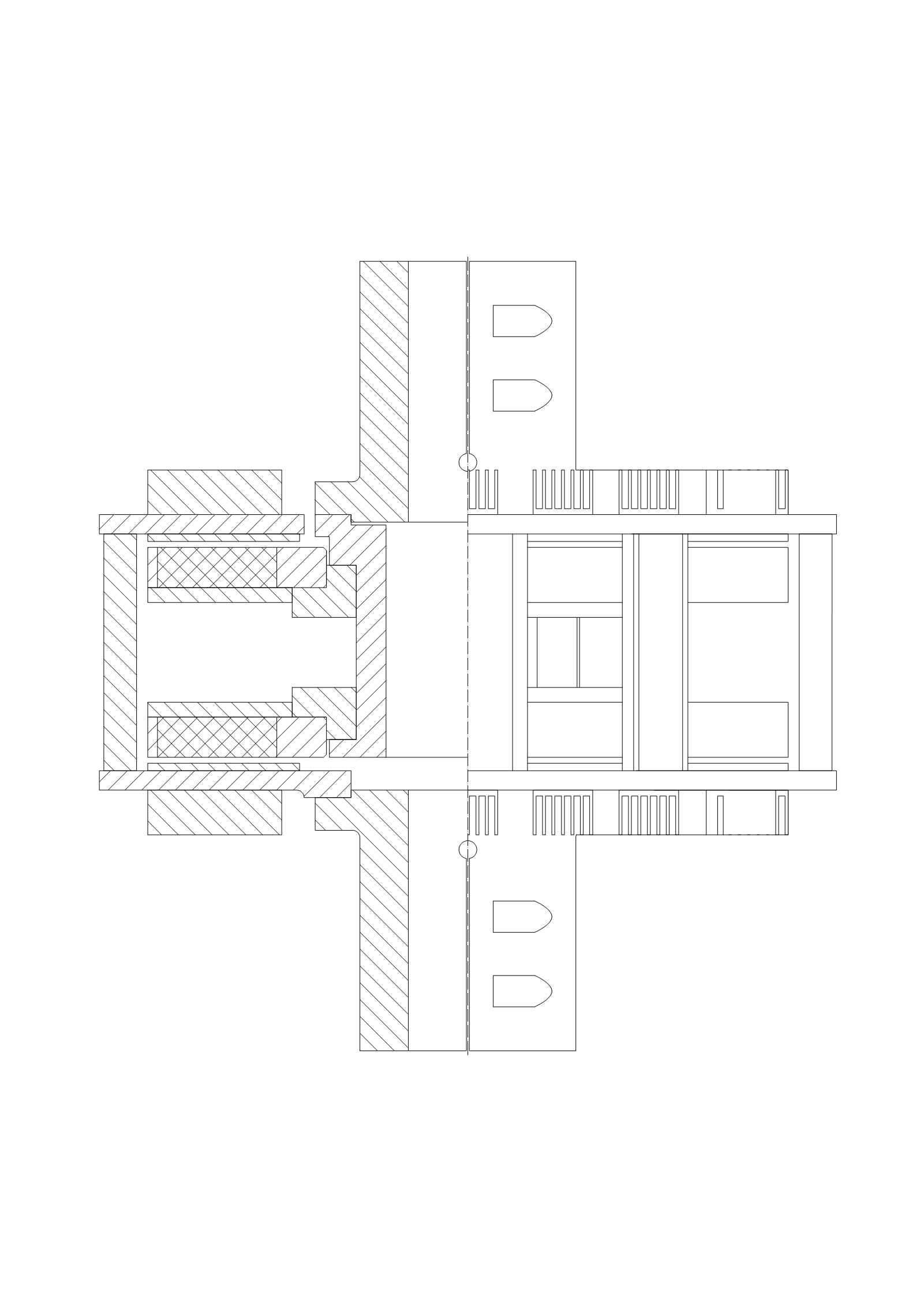

Conductor Assembly: Rotates within the magnetic field, inducing eddy currents to produce torque (as detailed in Sinopec’s CN 119382454 A patent).

Thermal Management Systems: Critical for dissipating heat from eddy currents, as emphasized in Sinopec’s drilling-focused PMC design.

2. Cutting-Edge Innovations in PMC Technology

2.1 Sinopec’s Drilling-Optimized PMC

Sinopec’s 2025 patent introduces a dual-layer conductor configuration to reduce operating temperatures by 15–20%. Applications in oil drilling demonstrate a 30% increase in component lifespan under high-torque conditions.

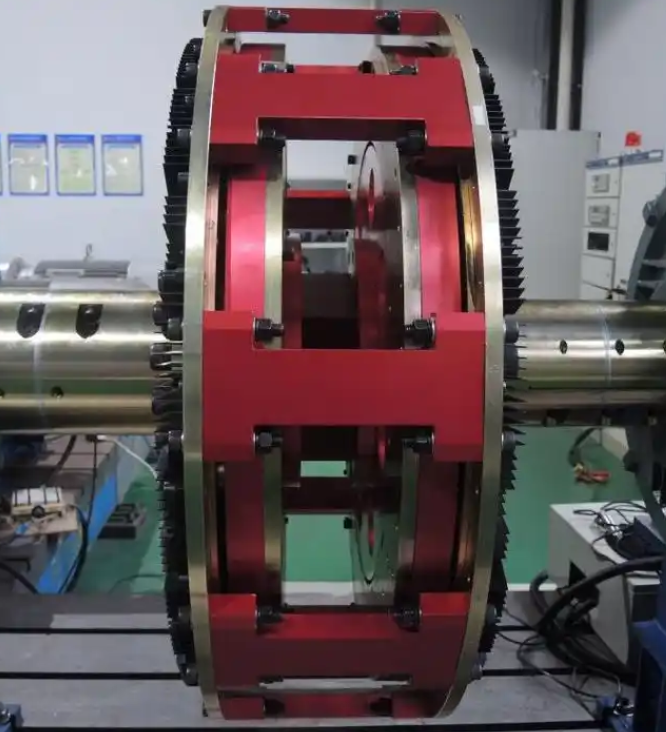

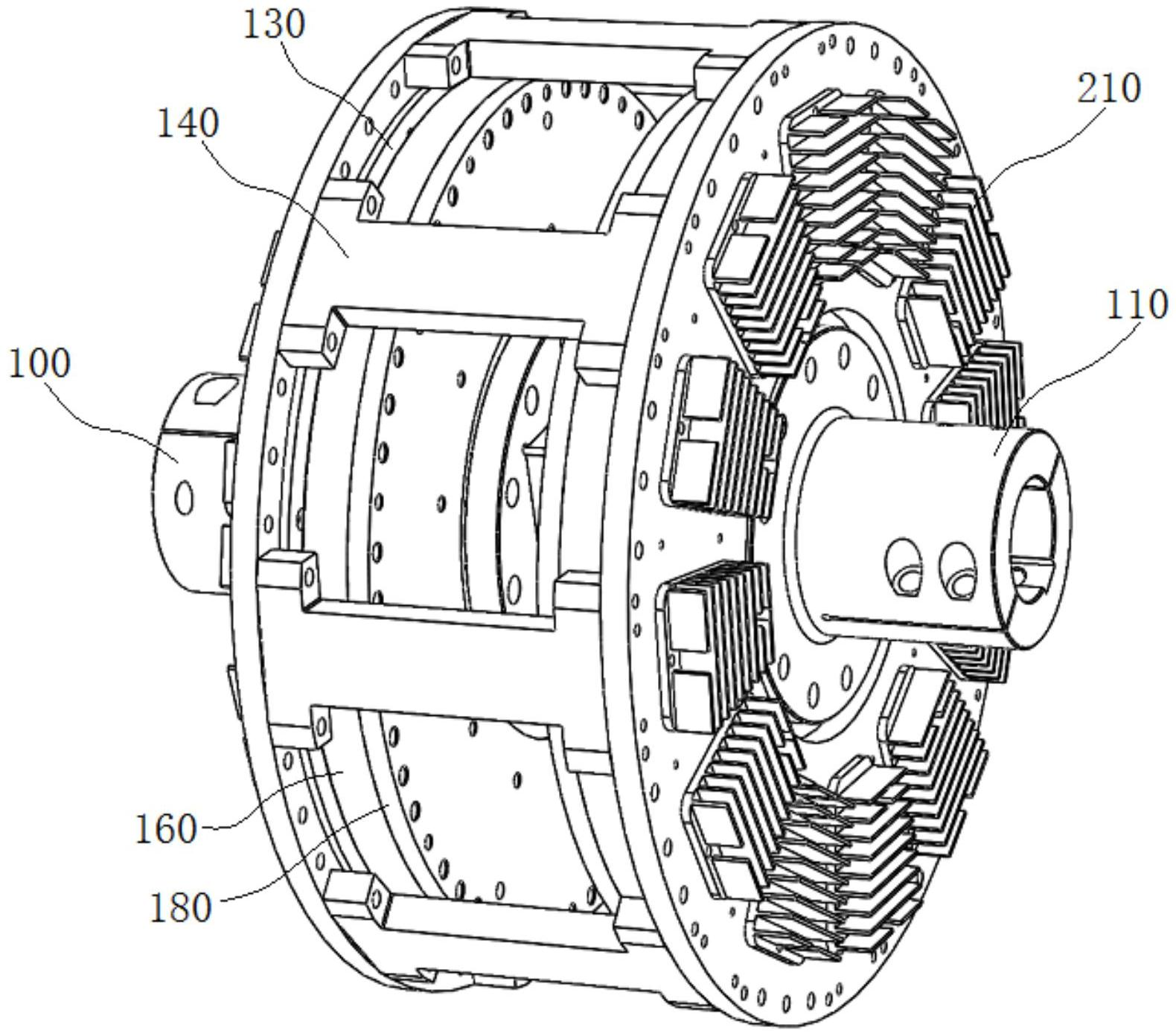

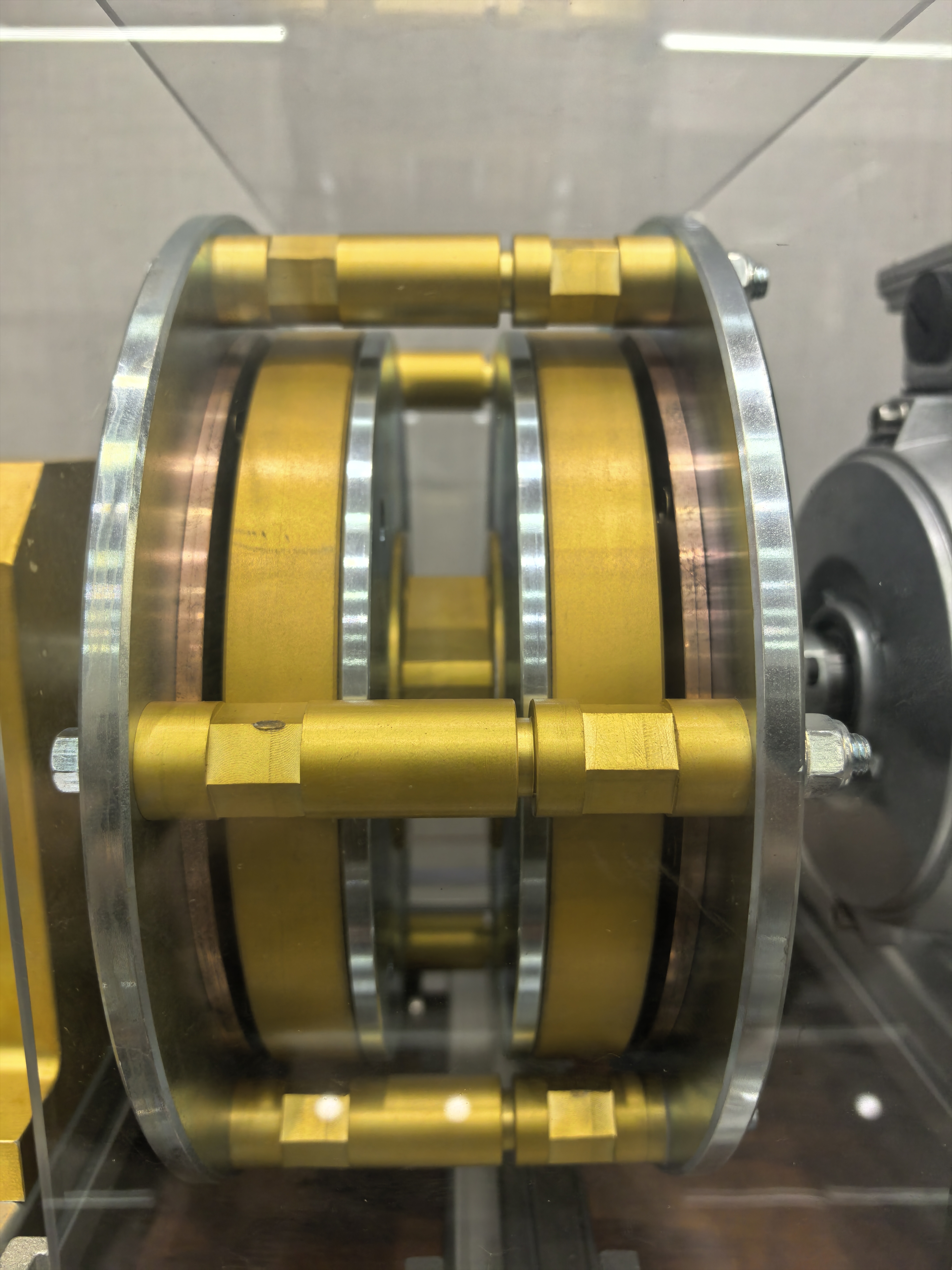

2.2 Jiangsu University’s Adjustable Dual-Drum Asynchronous PMC

This design (CN201520148142.2) leverages bilateral magnetic structures and orthogonal magnetization to enhance torque density by 40%. Its self-shielding effect minimizes flux leakage, making it ideal for heavy machinery and pump systems.

3. Permanent Magnetic Couplings Selection Criteria: A Five-Pillar Framework

3.1 Torque Requirements

Low Torque (<500 Nm): Single-drum PMCs with radial magnetization (cost-effective for HVAC systems).

High Torque (>5,000 Nm): Dual-drum designs like Jiangsu University’s model, utilizing axial-conical magnet arrangements.

3.2 Thermal Performance

Conductor Material: Copper-aluminum composites balance conductivity and weight.

Cooling Systems: Sinopec’s patent highlights integrated heat sinks and airflow channels for drilling rigs.

3.3 Environmental Adaptability

Corrosion Resistance: Stainless steel enclosures for marine applications.

Dustproofing: IP67-rated seals for mining and cement industries.

3.4 Energy Efficiency

Permanent Magnetic Couplings reduce energy losses by 12–18% compared to mechanical couplings, aligning with global carbon neutrality goals.

3.5 Cost-Benefit Analysis

Initial Cost: 20–30% higher than gear couplings.

Lifetime Savings: 50% lower maintenance and 25% energy reduction over 10 years.

4. Sector-Specific Applications

4.1 Oil & Gas Drilling

Sinopec’s PMCs now power 200+ deep-well rigs, slashing downtime by 45% through temperature-controlled conductors.

4.2 Wastewater Treatment

Jiangsu University’s adjustable PMCs enable variable-speed control in centrifugal pumps, cutting energy use by 22% in Shanghai’s Xinlong Plant.

4.3 Renewable Energy

Offshore wind farms adopt PMCs for gearless torque transmission, achieving 99.5% uptime in North Sea installations.

5. Market Trends & Future Outlook

2025 PMC Market Size: Projected at $4.2B, driven by Asia-Pacific industrial growth.

Next-Gen Tech: Hybrid PMCs with superconducting materials aim to double torque capacity by 2030.

Conclusion

From Sinopec’s thermal breakthroughs to Jiangsu University’s high-torque innovations, PMC selection now demands a nuanced understanding of operational parameters and sector needs. As industries prioritize sustainability and reliability, PMCs stand poised to redefine mechanical power transmission.