Case Study: Enhancing Reliability in High-Temperature Processing with Advanced Fluid Coupling Technology

Case Study: Enhancing Reliability in High-Temperature Processing with Advanced Fluid Coupling Technology

Introduction

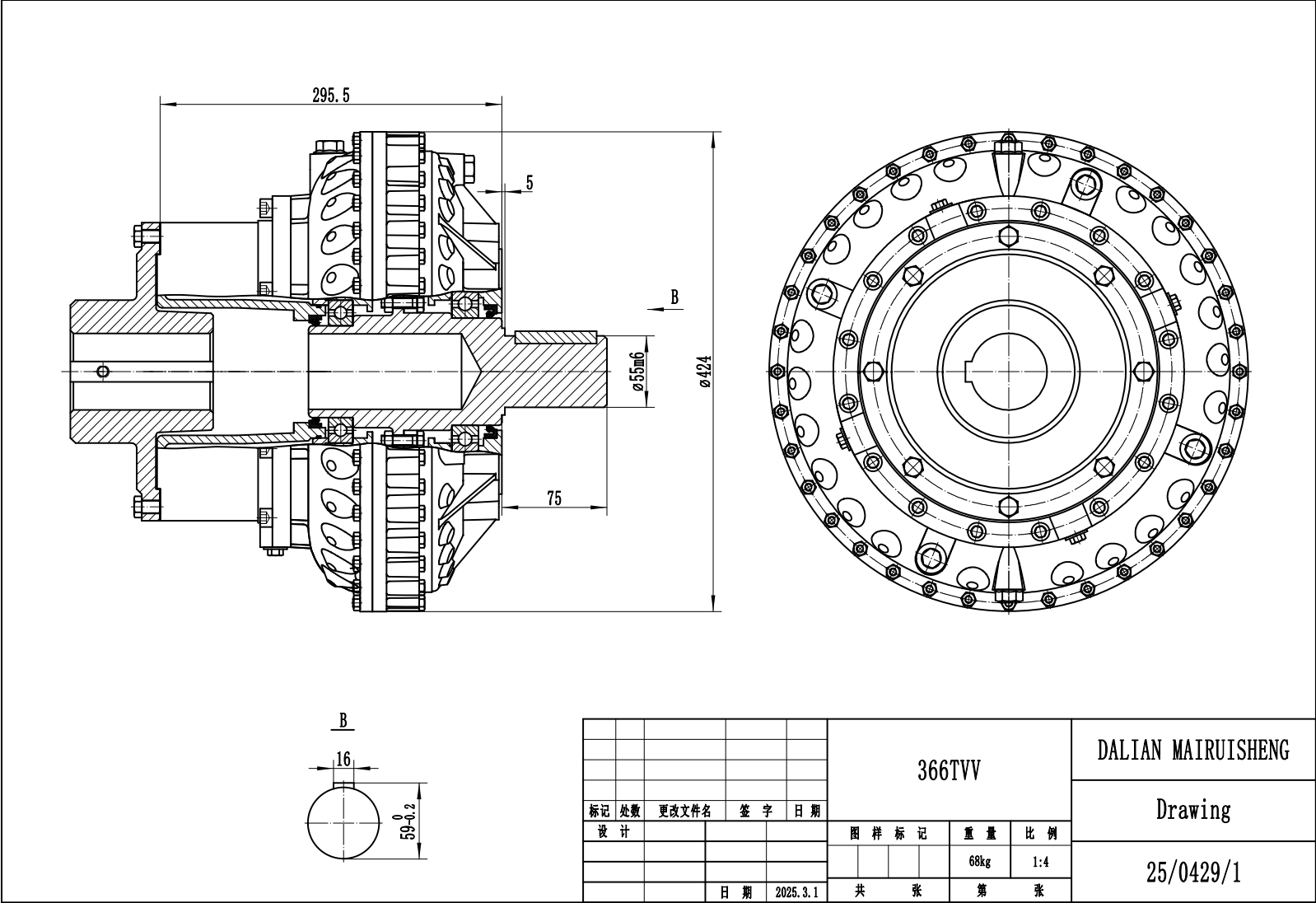

Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd., a specialist in innovative power transmission solutions, recently partnered with a major Chinese industrial plant to address persistent challenges in their high-temperature production line. The application of Dalian Mairuisheng's 366TVV model Fluid Coupling proved to be a decisive factor in significantly improving operational reliability, reducing maintenance costs, and enhancing energy efficiency.

Client Profile and Operational Challenge

The client, a leading Chinese factory in the metallurgical sector, operates a continuous casting process that demands exceptional reliability from its conveyor drive systems. The core of the problem was the plant's main conveyor, responsible for transporting red-hot slabs. The existing mechanical coupling system was plagued by:

Frequent failures due to extreme thermal stress and shock loads during start-up.

Excessive downtime for maintenance and component replacement.

High energy consumption caused by inefficient motor start-up against high inertial loads.

The plant required a robust, maintenance-light solution that could handle severe operating conditions while ensuring smooth and protected start-ups.

The Dalian Mairuisheng Solution: 366TVV Fluid Coupling

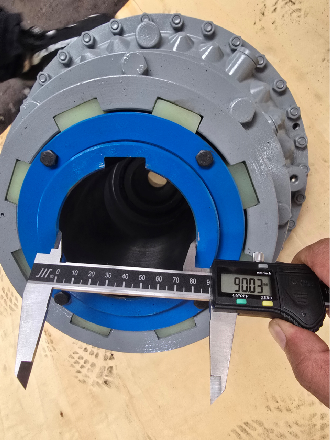

After a thorough site analysis, Dalian Mairuisheng engineers recommended and implemented their flagship Fluid Coupling, the model 366TVV. This specific Fluid Coupling is engineered for heavy-duty applications and offers several critical advantages for harsh industrial environments.

The core technology of the 366TVV Fluid Coupling involves transmitting torque hydrokinetically through a controlled volume of oil between an impeller (pump) and a runner (turbine). This design inherently provides an elastic connection between the motor and the driven equipment. The implementation of the 366TVV Fluid Coupling was strategic, designed to act as a protective buffer for the entire drive train.

Technical Implementation and Observed Benefits

The integration of the 366TVV Fluid Coupling into the conveyor's drive system yielded immediate and measurable improvements:

1. Elimination of Shock Loads and Equipment Protection: The elastic nature of the 366TVV Fluid Coupling allowed for a smooth, progressive acceleration of the heavily loaded conveyor belt. This eliminated the damaging shock torques that were previously transferred to the motor, gearbox, and conveyor structure. The plant reported a complete cessation of failures related to mechanical shock, drastically increasing the service life of downstream components.

2. Significant Reduction in Maintenance and Downtime: Unlike mechanical couplings that suffer from wear and tear, the 366TVV Fluid Coupling has no mechanical contacting parts that engage during start-up. Its "no-wear" operation during the most critical phase—acceleration—translated to a dramatic drop in maintenance needs. The client's maintenance teams confirmed that unscheduled downtime for the conveyor drive was reduced by over 70% in the six months following installation.

3. Improved Motor Starting Performance and Energy Savings: The 366TVV Fluid Coupling enables the motor to start under a minimal load, allowing it to reach its operational speed rapidly and with a significantly lower inrush current. For the client, this resulted in a reduction of start-up current peaks by approximately 40%, lowering the demand charges on their electrical system and reducing stress on the motor windings, thereby extending motor life.

4. Effective Vibration Damping and Misalignment Compensation: The 366TVV Fluid Coupling effectively dampened torsional vibrations originating from the motor or load, leading to smoother overall operation and reduced noise levels. Furthermore, its design offers a higher tolerance for minor misalignments compared to rigid couplings, providing an additional layer of protection for the machinery.

Conclusion and Long-Term Value

The successful deployment of the 366TVV Fluid Coupling at the Chinese metallurgical plant underscores Dalian Mairuisheng's commitment to delivering practical, high-performance engineering solutions. The 366TVV model Fluid Coupling demonstrated its superior capability as a core component for enhancing system reliability and operational economy in demanding applications.

By choosing the 366TVV Fluid Coupling, the client achieved a more resilient, efficient, and cost-effective production process. The project stands as a testament to how advanced Fluid Coupling technology can directly contribute to the bottom line by minimizing downtime, extending equipment lifespan, and optimizing energy use. Dalian Mairuisheng's 366TVV Fluid Coupling has set a new benchmark for performance and reliability in the client's operations.

About Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd.

Dalian Mairuisheng is a renowned manufacturer and solution provider in the field of power transmission, specializing in the design and production of a comprehensive range of coupling products, including high-quality Fluid Coupling systems. With a strong focus on innovation and customer-centric engineering, the company provides reliable solutions for industries worldwide, including mining, metallurgy, cement, and power generation.