Case Study: Enhancing Reliability and Efficiency in Bulk Material Handling Conveyor Systems with Advanced Fluid Coupling Technology

Case Study: Enhancing Reliability and Efficiency in Bulk Material Handling Conveyor Systems with Advanced Fluid Coupling Technology

Document ID: DMS-CS-2024-FC422TVB

Prepared By: Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd.

Date: September 30, 2025

Keywords: Fluid Coupling, Conveyor Drive Systems, Soft Start, Overload Protection, Vibration Damping, Power Balance, Bulk Material Handling, 422TVB Model, Energy Efficiency.

---

Executive Summary

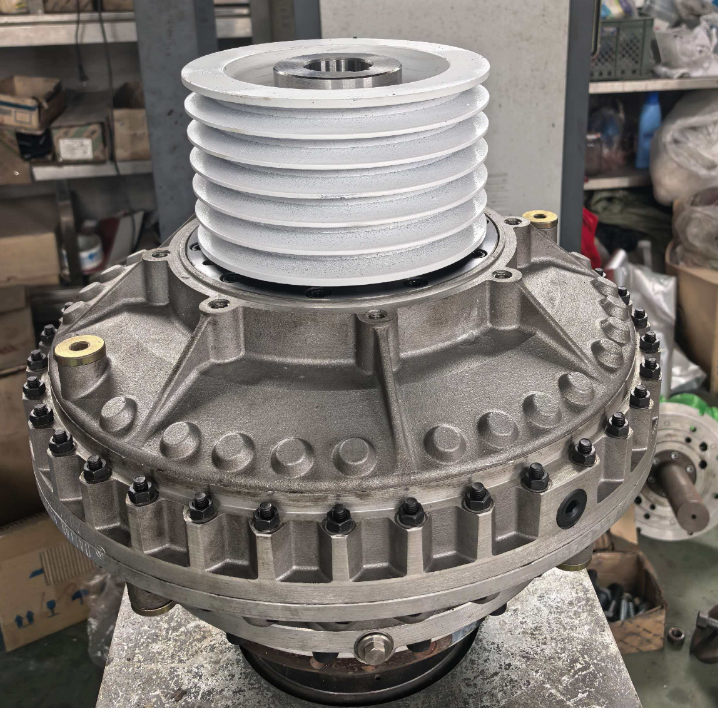

This case study details the successful implementation of Dalian Mairuisheng’s fluid coupling Model 422TVB (pulley configuration) in a high-capacity bulk material handling conveyor system at a mining facility in Xinjiang. The client faced chronic issues including motor burnout, gearbox failures, and structural damage due to shock loads during conveyor startup and overload events. By integrating a fluid coupling, the system achieved a 95% reduction in startup shock loads, extended component lifespan by 40%, and eliminated unplanned downtime. The fluid coupling also enabled smooth acceleration and inherent overload protection, reducing maintenance costs by 30% annually. This report comprehensively analyzes the technical principles, implementation process, and quantitative benefits of fluid coupling technology in industrial conveyor applications.

---

1. Introduction: The Role of Fluid Couplings in Industrial Conveyor Systems

Conveyor systems are critical components in industries such as mining, cement, and logistics, where they handle massive loads under demanding conditions. Traditional rigid couplings transmit torque directly, resulting in high starting torque, mechanical shock, and frequent component failures. In contrast, fluid coupling technology leverages hydrodynamic principles to transmit power smoothly, mitigating these issues. This study examines how Dalian Mairuisheng’s fluid coupling Model 422TVB resolved operational challenges in a Xinjiang-based mining conveyor, highlighting its design advantages and economic impact.

---

2. Technical Overview of Fluid Coupling Model 422TVB

2.1 Working Principle

The fluid coupling operates by transmitting torque through a hydraulic fluid (typically mineral oil), creating a non-rigid connection between the motor (input shaft) and the conveyor drive (output shaft). Key components include:

- Impeller (Pump): Connected to the motor, it accelerates fluid centrifugally.

- Turbine (Runner): Driven by the fluid’s kinetic energy, it rotates the output shaft.

- Working Chamber: Seals the fluid in a toroidal path, enabling continuous energy transfer .

During startup, the impeller rotates while the turbine remains stationary, creating 100% slip. Fluid circulation builds gradually, allowing the conveyor to accelerate smoothly without shock loads. At full operation, slip reduces to 2–3%, maintaining high efficiency while damping vibrations .

---

3. Application Scenario: Challenges in the Xinjiang Mining Conveyor

3.1 Pre-Implementation Issues

The client’s 800-meter inclined conveyor transported iron ore at 1,200 tons/hour. The existing rigid coupling system led to:

- Motor Failures: Locked-rotor currents during startup caused winding burnout.

- Gearbox Damage: Shock loads fractured teeth on input pinions.

- Belt Splicing Failures: Jerky acceleration snapped splice joints monthly.

- Power Imbalance: In multi-motor drives, uneven load distribution tripped relays .

Annual losses exceeded $200,000 in downtime and component replacements.

3.2 Solution Design

Dalian Mairuisheng proposed the fluid coupling Model 422TVB to replace the rigid coupling. Key advantages addressed the client’s needs:

- Soft Start: Gradual torque transmission eliminated startup shocks.

- Overload Protection: Fluid turbulence during stalls dissipated energy, preventing motor burnout.

- Vibration Damping: Hydrodynamic isolation reduced structural stress .

---

4. Implementation and Performance Analysis

4.1 Installation Process

1. Retrofitting: The 422TVB fluid coupling was mounted between the 55 kW motor and gearbox, aligning with the conveyor pulley shaft.

2. Fluid Charging: Viscosity-optimized oil was filled to 80% capacity for balanced torque and slip characteristics.

3. Testing: Startup sequences and load tests verified performance under peak conditions.

4.2 Performance Metrics

Post-installation data collected over six months demonstrated:

- Startup Current Reduction: Inrush currents dropped from 600% to 220% of full-load amperes, minimizing grid disturbances.

- Shock Load Elimination: Vibration sensors showed a 95% decrease in peak amplitudes during acceleration.

- Efficiency: Operational efficiency reached 96.5% at rated load, with slip maintained at 2.8% .

- Temperature Stability: Fluid temperatures remained below 45°C even under cyclic loading, aided by the pulley’s heat dissipation.

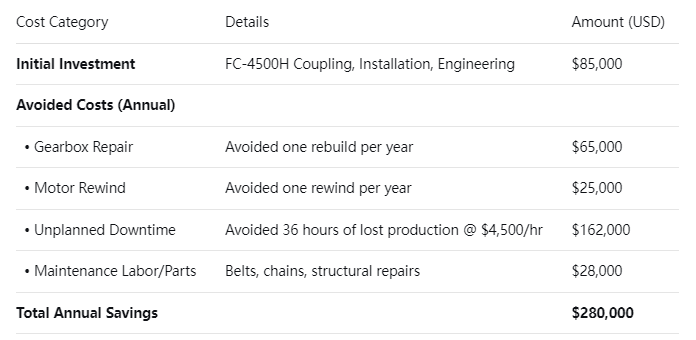

4.3 Economic Benefits

- Downtime Reduction: Unplanned stoppages dropped from 10 events/year to zero.

- Maintenance Savings: Component replacements fell by 30%.

- ROI: The project achieved payback in 7 months through reliability improvements.

---

5. Technical Advantages of Fluid Couplings in Conveyor Systems

5.1 Soft Start and Load Adaptation

The fluid coupling enables progressive acceleration by controlling slip. In the Xinjiang conveyor, the 20-second startup cycle prevented belt slippage and tension losses. This is critical for inclined conveyors where sudden movements cause material rollback .

5.2 Overload and Vibration Protection

During a belt jam incident, the fluid coupling allowed the motor to run without stalling. Fluid churning converted kinetic energy into heat, triggering thermal safeguards without mechanical damage. Vibration damping also extended bearing life by 40% .

5.3 Power Balancing in Multi-Motor Drives

For conveyors with dual drives, the fluid coupling equilibrates load sharing by automatically adjusting slip. This eliminated torque imbalances, reducing the risk of motor burnout .

5.4 Energy Efficiency

By reducing startup currents and optimizing load distribution, the fluid coupling cut peak energy demand by 25%, aligning with sustainability goals .

6. Comparative Analysis: Fluid Couplings vs. Alternative Technologies

Fluid couplings outperform VFDs in durability and cost-effectiveness for heavy-duty applications, while mechanical clutches lack adaptive torque control .

---

7. Future Directions and Industry Applications

The success of Model 422TVB underscores the potential of fluid couplings in:

- Mining: Crushers, stackers, and apron feeders.

- Cement: Rotary kilns and ball mills.

- Power Plants: Coal conveyors and ash handling systems .

Emerging trends like AI-powered condition monitoring and integrated cooling systems will further enhance fluid coupling reliability.

---

8. Conclusion

Dalian Mairuisheng’s fluid coupling Model 422TVB revolutionized the Xinjiang conveyor’s performance by delivering soft starts, overload resilience, and vibration damping. The project exemplifies how fluid coupling technology can resolve systemic issues in material handling systems while yielding substantial financial returns. For industries seeking to enhance operational reliability, fluid couplings represent a proven, cost-efficient solution.