Fluid Coupling Characteristics, Advantages, and Benefits: The Intelligent Heart of Robust Drive Systems

2025-12-22 14:39Fluid Coupling Characteristics, Advantages, and Benefits: The Intelligent Heart of Robust Drive Systems

In the demanding world of industrial power transmission, the quest for reliability, protection, and operational smoothness is paramount. The fluid coupling, a time-tested yet continually vital component, stands as a cornerstone technology in heavy-duty applications worldwide. From mining conveyors and crushers to mill drives, pump systems, and marine propulsion, the intelligent working principle of the fluid coupling offers a unique blend of protection and performance. This article delves into the core characteristics, multifaceted advantages, and tangible benefits that make the fluid coupling an indispensable element in modern industrial systems.

Core Principle: A Masterpiece of Hydrodynamic Engineering

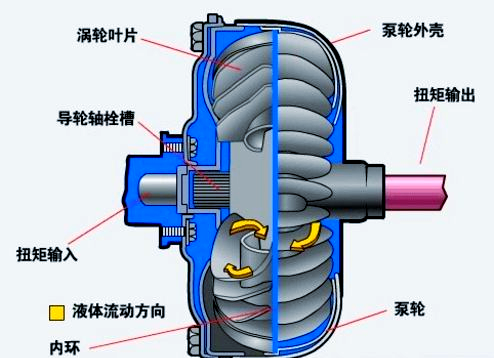

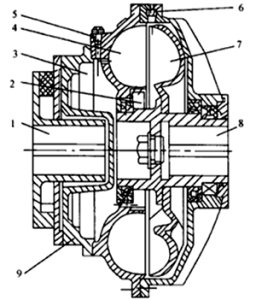

At its essence, a fluid coupling is a hydrodynamic device that transmits rotational power from a prime mover (like an electric motor or diesel engine) to a driven machine without any mechanical contact. It consists of two key elements housed in a sealed chamber filled with a precise volume of operating fluid, typically oil: the impeller (or pump wheel) connected to the input shaft and the runner (or turbine wheel) connected to the output shaft.

The fluid coupling can change the energy transfer in the drive system in many ways through their operating principle. The required torque and power transfer characteristics as well as the impact on the overall system performance basically determine the selection of the fluid coupling. When the input shaft rotates the impeller, it imparts kinetic energy to the fluid. This energized fluid is then directed onto the blades of the runner, causing it to rotate and thus transmitting torque to the output shaft. This purely hydrodynamic connection is the source of all its remarkable characteristics.

Defining Characteristics: The Hallmarks of Fluid Coupling Performance

The operational behavior of a fluid coupling is defined by several inherent characteristics:

1. Soft Start & Load Ramp-Up: The fluid coupling allows the motor to start rapidly against a minimal load (the inertia of the impeller and half the fluid), dramatically reducing inrush current. Torque is then smoothly transferred to the driven machine as the fluid accelerates, providing a controlled, shock-free ramp-up to full speed.

2. Torque Conversion and Limitation: The transmitted torque is proportional to the square of the input speed and the fifth power of the coupling's size. Crucially, the maximum torque a fluid coupling can transmit is inherently limited by its design and fill level, creating a natural overload cut-off.

3. Slip: A small, constant speed difference (slip of typically 2-4%) exists between input and output shafts under normal operating conditions. This slip is essential for torque transmission and increases temporarily during acceleration or overload.

4. Vibration Damping and Isolation: The fluid medium effectively decouples the two shafts, isolating and damping torsional vibrations from the motor or the load. This protects the entire drive train from resonance and cyclical stresses.

5. Self-Regulating Behavior (Especially in Torque-Limiting Types): These transmission characteristics are particularly important for torque-limited fluid couplings because their working principle is without external control. They react autonomously to load changes. Under a sudden overload, the slip increases significantly, limiting the output torque and allowing the motor to continue running near its rated speed, often preventing a stall.

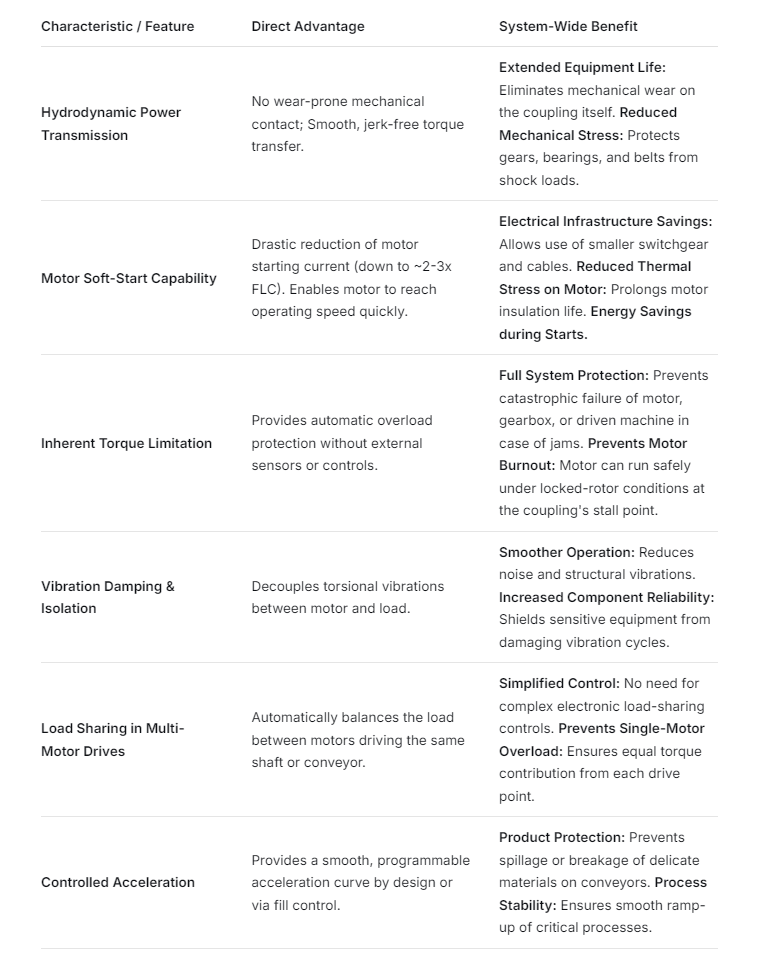

Advantages & Benefits: Transforming System Economics and Reliability

The characteristics of the fluid coupling translate directly into significant operational and economic advantages for the entire drive system. The following table summarizes the most important features of torque-limiting fluid couplings and describes the advantages and benefits gained by the entire system:

Conclusion: A Strategic Investment for Long-Term Performance

The fluid coupling is far more than a simple power transmission component. It is an intelligent system safeguard that enhances the performance, protects the capital investment, and optimizes the operational cost of the entire drive train. Its self-acting, maintenance-friendly, and robust design makes it a uniquely reliable solution where reliability counts the most. In an era focused on operational efficiency, asset protection, and reducing total cost of ownership, the fluid coupling remains a profoundly relevant and indispensable technology, proving that elegant engineering principles deliver enduring value.

About Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd

Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd is a global leader in the design and manufacture of advanced power transmission solutions, specializing in high-performance fluid couplings for the most demanding industrial applications. With decades of engineering expertise, we provide products that set the standard for reliability, efficiency, and system protection.