Dalian Mairuisheng: A 20-Year Pillar of Power Transmission Excellence, Forging the Future with Fluid and Magnetic Coupling Expertise

2026-02-02 08:36Dalian Mairuisheng: A 20-Year Pillar of Power Transmission Excellence, Forging the Future with Fluid and Magnetic Coupling Expertise

Celebrating two decades of industrial service, Dalian Mairuisheng Transmission Mechanism Equipment Co., Ltd. stands as a definitive specialist in engineered power transmission solutions. From its foundation in 2006, the company has been dedicated to the research, design, and precision manufacturing of a comprehensive range of Fluid Coupling and Hydrodynamic Coupling systems. This deep, twenty-year focus has cultivated an unparalleled mastery of torque management, load protection, and customized mechanical design. Furthermore, this extensive experience forms the robust foundation for its advanced Magnetic Coupling technology, positioning Mairuisheng as a rare and versatile partner capable of providing the optimal drive solution, whether based on fluid dynamics or magnetic flux principles.

The journey of two decades has transcended mere manufacturing. It represents an accumulated legacy of solving thousands of unique application challenges across China's core industries—from the dusty, high-impact environments of coal mining to the relentless, humid operations of port logistics and the high-torque demands of steel and cement production. This evolution from a skilled manufacturer to a consultative engineering partner defines the Dalian Mairuisheng identity: a company where proven tradition meets adaptive innovation to deliver unwavering reliability.

Part 1: The 20-Year Advantage: Experience Codified into Reliability

Twenty years in heavy industry is not just a measure of time; it is a vast repository of empirical data and perfected processes. Dalian Mairuisheng's longevity is built upon a core philosophy of "robustness first." Every Fluid Coupling that leaves its Dalian factory carries the weight of this experience. The company's engineers have witnessed firsthand the long-term performance of different material grades, sealing technologies, and impeller designs across countless operating cycles. This has led to the development of proprietary design protocols and material specifications that prioritize long-term durability over short-term cost-saving. For a global client, this translates to a Hydrodynamic Coupling that is not just a purchased component, but a vessel of refined, battle-tested engineering knowledge, promising extended mean time between failures (MTBF) and predictable performance throughout its service life.

Part 2: Breadth of Capability: A Complete Fluid Coupling Portfolio

The company's expertise is showcased in its ability to design and produce an exceptionally wide spectrum of Fluid Coupling types, tailored to specific mechanical functions:

- Standard Fixed-Fill Couplings: Engineered for simple, dependable torque transmission and motor load protection in applications like conveyor belts, pumps, and fans.

- Variable-Speed (Variable-Fill) Couplings: Designed for processes requiring controlled start-up and adjustable operational speed, offering significant energy savings in centrifugal pump and fan applications.

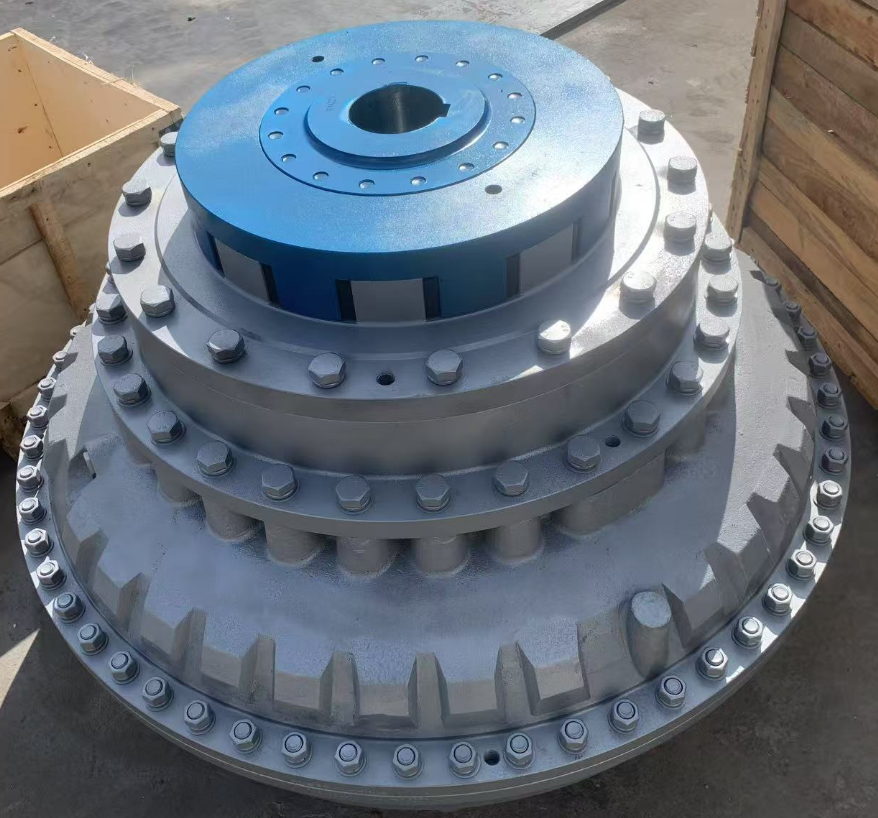

- Highly Customized Specials: This is where Dalian Mairuisheng's engineering prowess shines. The portfolio includes complex variants such as Hydrodynamic Coupling with Double Fluid Units for extreme high-inertia starts, units with enlarged delayed filling chambers for super-smooth acceleration, and space-saving integrated designs like Fluid Coupling with Brake Disc or with pulley configurations. This extensive range ensures that for virtually any industrial drive challenge requiring a Hydrodynamic Coupling, a purpose-engineered solution exists or can be created.

Part 3: Depth of Design: From Concept to Certified Product

Dalian Mairuisheng's role as a true supplier extends far beyond production. It encompasses full in-house design capability. When presented with a new application—be it for a mega-watt ball mill or a specialized marine thruster—the engineering team initiates a rigorous process. This involves precise torque calculation, thermal analysis, finite element analysis (FEA) for structural integrity, and dynamic modeling of start-up characteristics. Prototypes are built and tested on in-house rigs that simulate real-world loads. This closed-loop process from CAD model to validated product ensures that every custom Fluid Coupling performs as theoretically intended under actual operating conditions. It is this end-to-end control over the design-and-validate cycle that transforms a client's performance requirement into a guaranteed mechanical reality.

Part 4: Synergistic Technology: The Magnetic Coupling Advantage

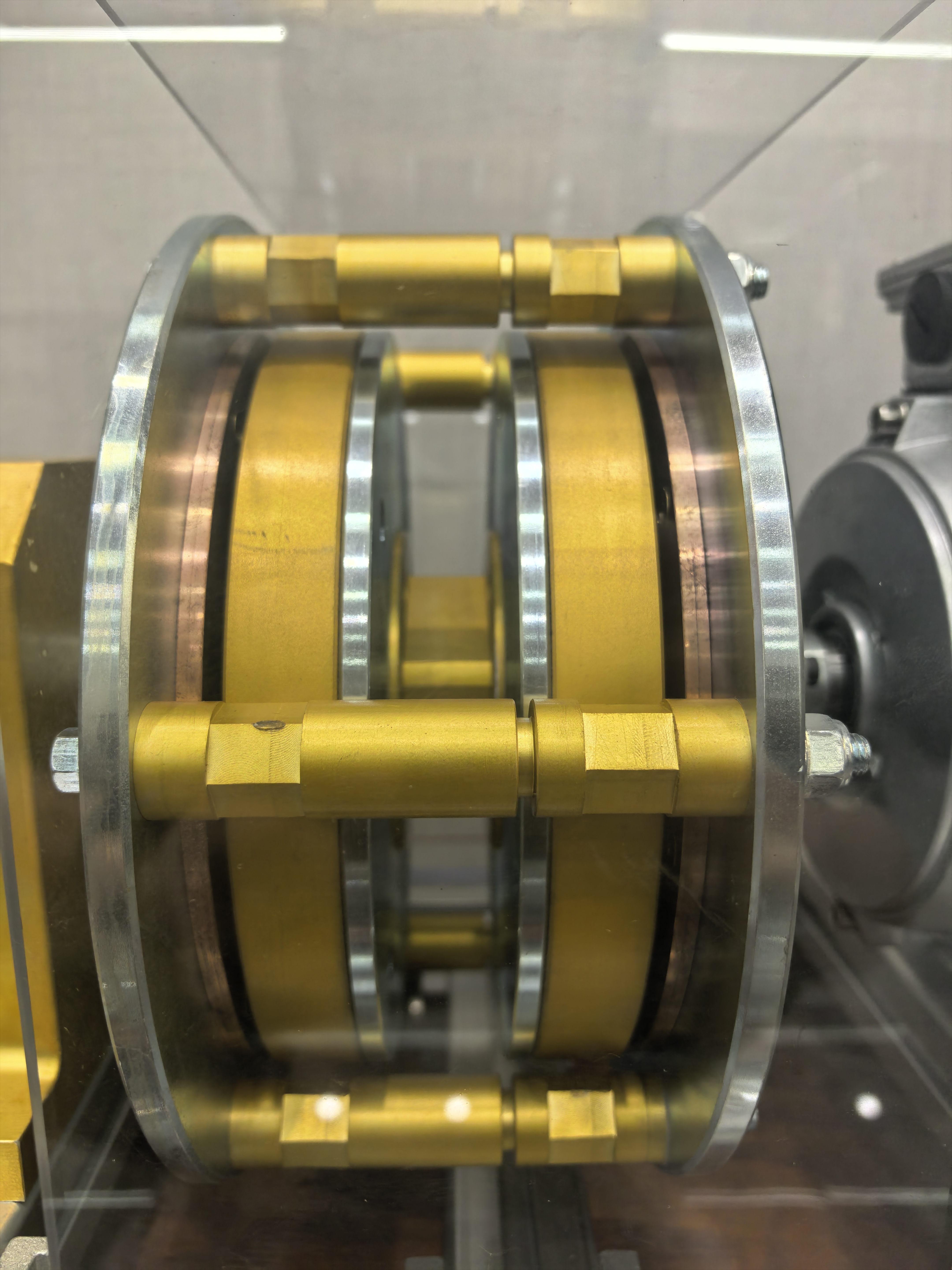

Building upon its profound understanding of power transmission challenges, Dalian Mairuisheng has strategically developed its Magnetic Coupling technology. This is not a separate venture but a logical extension of its mission to solve torque transfer problems. While a Fluid Coupling excels in soft-start and overload protection through visco

us shear, a Magnetic Coupling provides absolute torque transmission through an air gap, ensuring complete hermetic sealing. This makes it ideal for applications where leakage is unacceptable, such as in chemical processing, submerged pumps, or cleanroom environments. The company's deep mechanical design experience ensures that its Magnetic Coupling units are not just magnet carriers but are engineered with the same focus on bearing life, thermal management, and structural rigidity as its flagship Hydrodynamic Coupling products. This dual-technology mastery allows Dalian Mairuisheng to offer truly impartial consultation, recommending the most effective technology—fluid or magnetic—for the client's specific need.

Part 5: The Foundation of Trust: Manufacturing Integrity and Global Vision

Every coupling is backed by a vertically integrated manufacturing facility in Dalian. The process, refined over twenty years, encompasses precision sand casting, CNC machining, dynamic balancing to high-grade standards (e.g., G2.5), and comprehensive run-in testing. "Our reputation is cast in every housing and balanced on every rotor," says the Head of Manufacturing. "We control the entire value chain, which allows us to guarantee the quality that our two-decade brand name represents." As the company looks outward, it brings this legacy of trust to the global market. It positions itself not as a low-cost alternative, but as a high-value partner whose twenty years of focused Fluid Coupling and Magnetic Coupling expertise translates into lower total cost of ownership through superior reliability, reduced downtime, and perfectly matched drive solutions for partners worldwide.