Innovation in Motion: How Advanced Industrial Turbo Couplings are Redefining Power Transmission Efficiency and Reliability

2025-10-28 09:20Innovation in Motion: How Advanced Industrial Turbo Couplings are Redefining Power Transmission Efficiency and Reliability

In the relentless drive for industrial efficiency and operational resilience, the core components that form the backbone of power transmission systems are undergoing a quiet revolution. At the heart of this transformation lies the advanced Industrial Turbo Coupling, a sophisticated evolution of the fundamental Fluid Coupling principle. Today, leading engineering firms and manufacturers are increasingly recognizing that the strategic implementation of a high-performance Fluid Coupling is no longer a mere component choice, but a critical strategic decision impacting everything from energy consumption to operational uptime. The modern Industrial Turbo Coupling represents the pinnacle of this technology, offering unparalleled solutions for the most demanding applications across mining, power generation, and heavy processing.

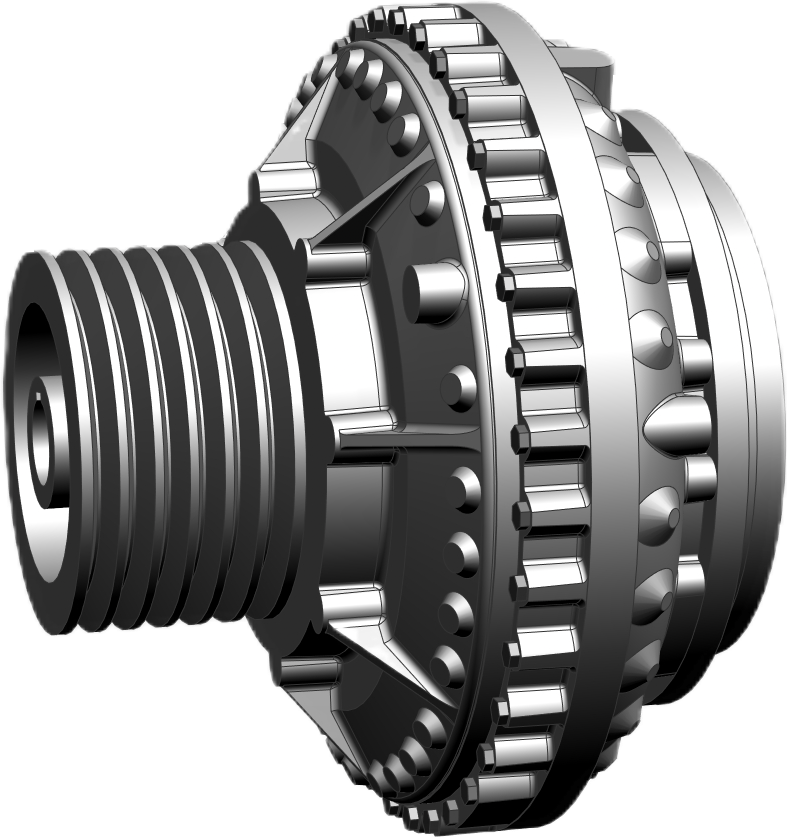

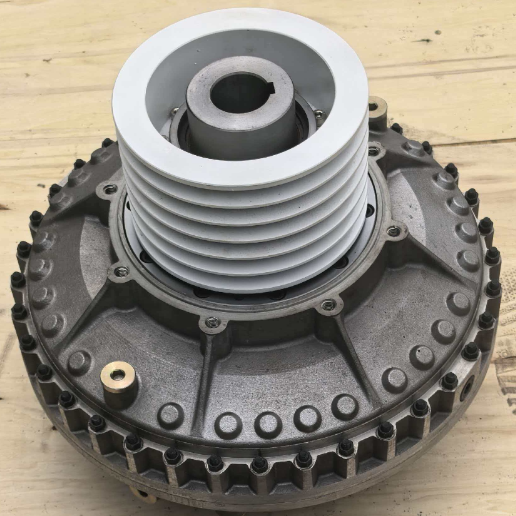

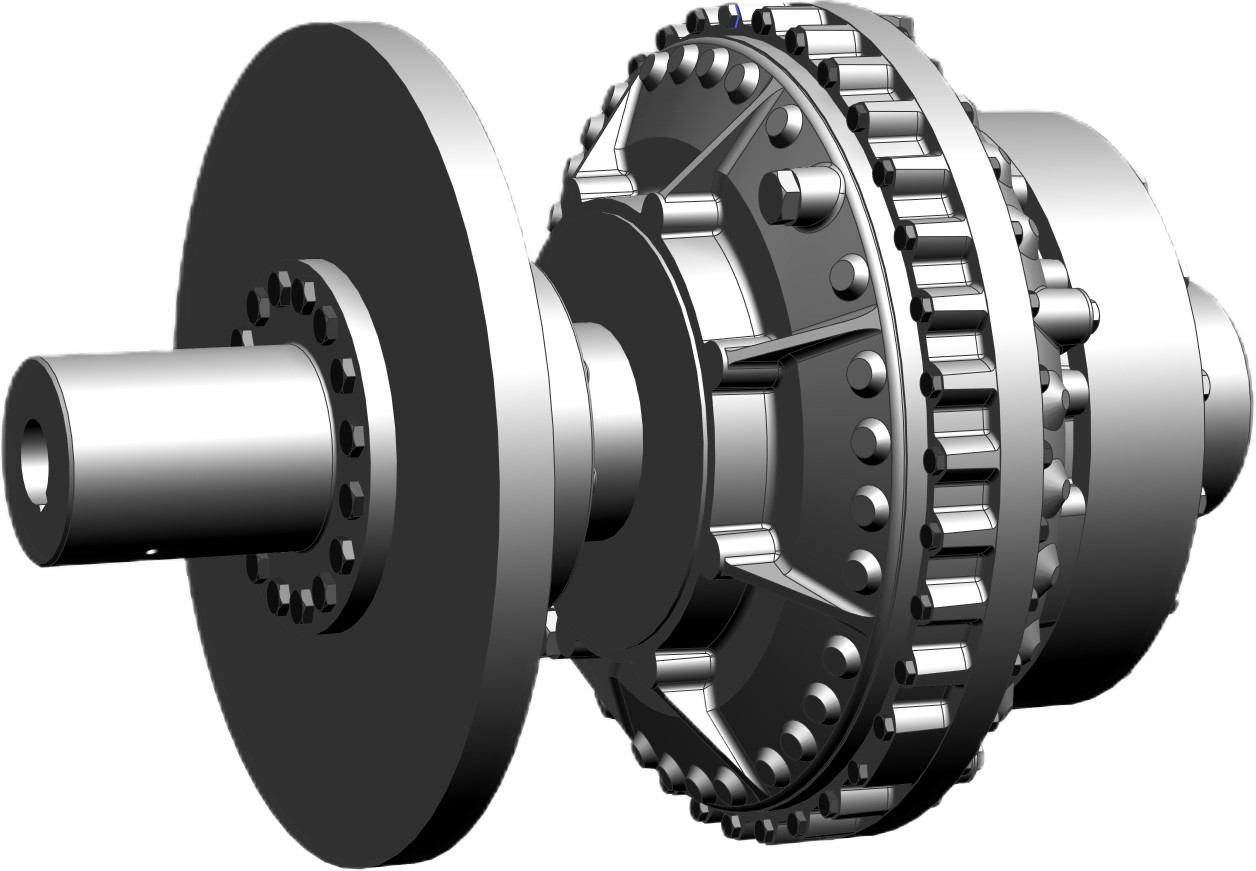

For decades, the challenge of connecting a prime mover, like an electric motor, to a driven load has been central to mechanical engineering. Direct connections often lead to devastating shock loads, severe misalignment issues, and catastrophic failure during start-up. The introduction of the Fluid Coupling provided the first elegant solution. The fundamental principle of a Fluid Coupling is ingenious in its simplicity: it uses a hydraulic fluid, typically oil, to transmit torque kinetically from an input impeller (pump) to an output runner (turbine). This fluid-based power transmission inherently provides smooth, gradual acceleration, protecting both the motor and the driven equipment from damaging stress peaks. This core benefit of the standard Fluid Coupling laid the groundwork for all subsequent developments.

The Industrial Turbo Coupling is the direct, highly engineered descendant of this basic concept. While a standard Fluid Coupling excels in basic soft-start applications, the Industrial Turbo Coupling incorporates advanced features such as variable-fill technology and integrated delay chambers. These features allow for precise control over the torque transmission characteristics and starting sequences. "The difference between a basic Fluid Coupling and a modern Industrial Turbo Coupling is like the difference between a simple on-off switch and a smart, programmable motor controller," explains Dr. Elena Richter, Head of Engineering at Voith Turbo. "The advanced Industrial Turbo Coupling doesn't just connect; it manages the power, optimizes the flow, and actively protects the entire drive train."

The operational benefits of specifying a robust Industrial Turbo Coupling are substantial and directly impact the bottom line. The most significant advantage remains the dramatic reduction in start-up current. By allowing the motor to start under a minimal load and accelerate to near-full speed before gradually transferring torque to the load, an Industrial Turbo Coupling can reduce inrush current by up to 40-50% compared to direct-on-line starters. This not only leads to significant energy savings but also reduces the demand on electrical infrastructure, potentially allowing for the use of smaller, more cost-effective transformers and switchgear. The inherent flexibility of any Fluid Coupling is preserved and enhanced in the Industrial Turbo Coupling, accommodating significant misalignment and damping torsional vibrations that would otherwise degrade bearings and equipment.

The application spectrum for the heavy-duty Industrial Turbo Coupling is vast and critical to global industry. On a conveyor belt system stretching for kilometers in a mining operation, the controlled start-up provided by an Industrial Turbo Coupling prevents belt snap and spillage, extending the system's lifespan. In a centrifugal pump scenario, it eliminates water hammer, protecting valves and pipelines. For crushers and grinders in mineral processing, the Industrial Turbo Coupling acts as a hydrodynamic fuse, stalling the machine without damaging the motor in the event of a jam. In every case, the core principle of the Fluid Coupling—torque transmission via fluid dynamics—is leveraged to its maximum potential by the engineered design of the Industrial Turbo Coupling.

The evolution of the Industrial Turbo Coupling is closely tied to the global push for sustainability and Industry 4.0. Modern units are designed for higher efficiency, minimizing fluid churning losses at operational speed. Furthermore, the latest generation of Industrial Turbo Coupling systems can be equipped with sensors to monitor fill level, temperature, and vibration. This data can be integrated into plant-wide predictive maintenance systems, alerting operators to potential issues before they lead to unplanned downtime. The reliability of a well-maintained Fluid Coupling is legendary, and this new smart functionality elevates it to a new level of operational intelligence.

Looking forward, the market for advanced power transmission solutions like the Industrial Turbo Coupling is poised for steady growth. As industries worldwide seek to optimize energy usage, enhance operational safety, and maximize the lifespan of capital-intensive machinery, the role of the intelligent Fluid Coupling becomes increasingly central. The journey from the basic Fluid Coupling to the smart, connected Industrial Turbo Coupling of today is a testament to continuous engineering innovation, proving that even foundational technologies can be refined to meet the challenges of the modern industrial landscape.