Case Study: Solving Stability Problems in Chemical Waste Treatment with Advanced Magnetic Coupler Technology

1 Overview of Magnetic Coupling Technology

A Magnetic Coupling (also known as a permanent magnet coupling) is an advanced transmission device that achieves non-contact transmission of mechanical energy through the interaction of magnetic fields between permanent magnets. Its core working principle is based on the magnetic field coupling effect, primarily consisting of three key components: an outer rotor, an inner rotor, and a containment shell. The outer rotor connects to the power source (such as an electric motor), the inner rotor connects to the working machine (such as a pump or agitator), and the containment shell, as a static sealing component fixed to the housing, completely isolates the rotating internal parts from the external environment. This ingenious structural design allows the driving and driven ends to transmit torque efficiently through the push-pull action of the magnetic field without the need for a physical connection.

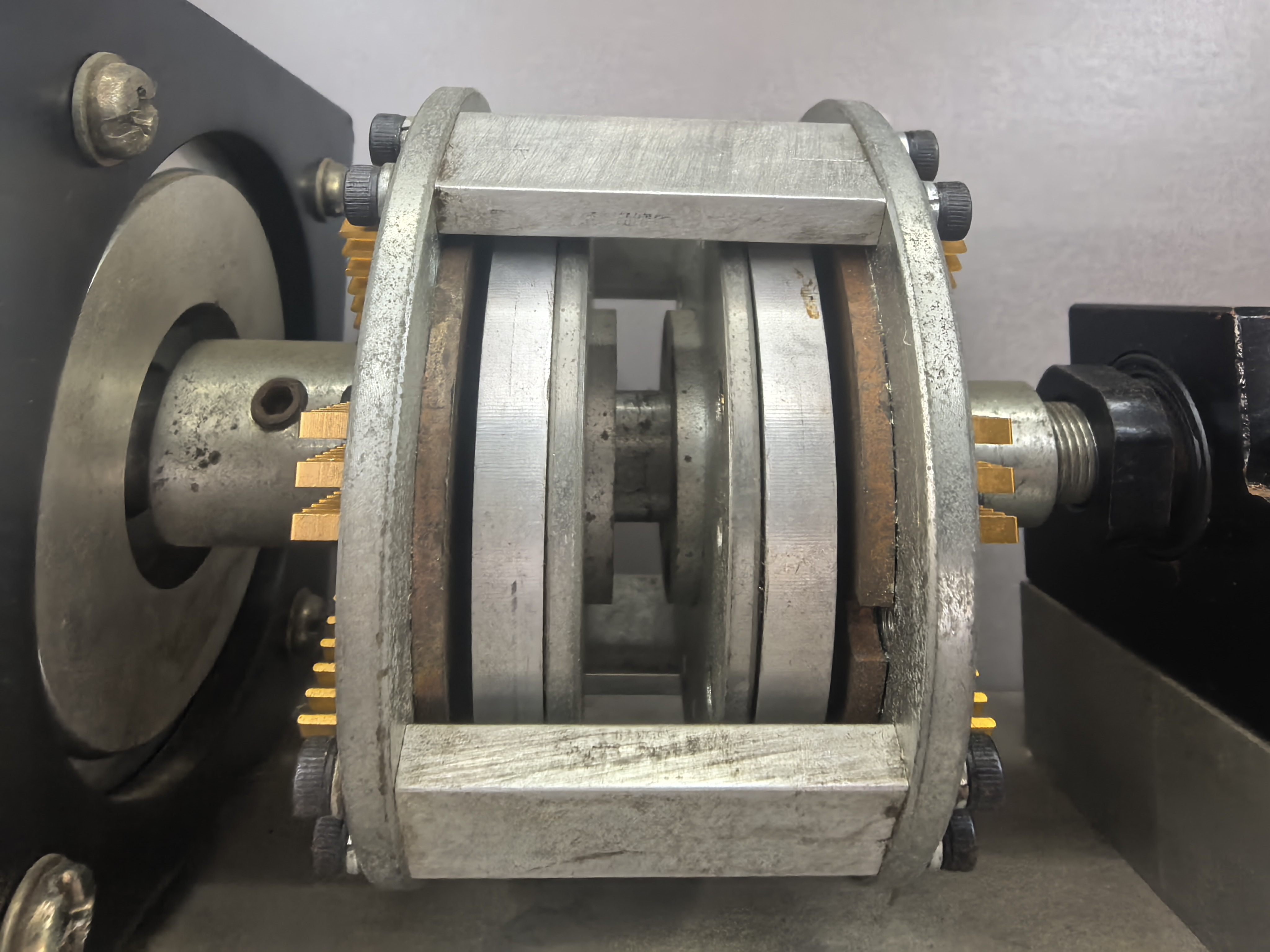

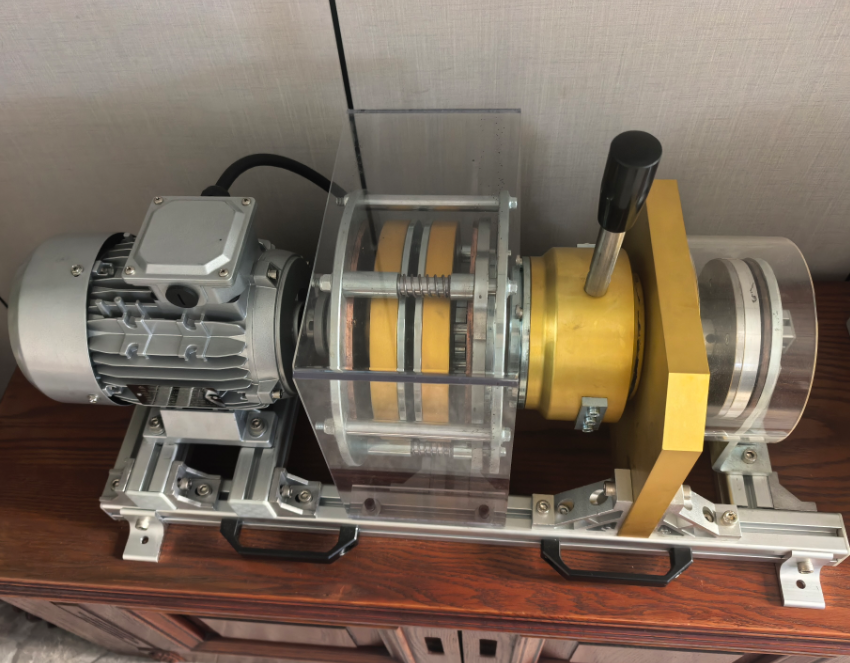

In practical applications of Magnetic Couplings, there are mainly two structural types: cylindrical and disc type. In the cylindrical permanent magnet coupling, magnetic poles are distributed on the inner surface of the outer ring of one half-coupling and the outer surface of the inner ring of the other half-coupling, with the barrier being cylindrical. This structure has a larger transmission radius than the disc-type permanent magnet coupling, can transmit greater torque, and imposes very little axial force, making it the commonly adopted structural type in industrial applications. In contrast, the magnetic blocks in the disc-type Magnetic Coupling are arranged on two identical flat discs. Although simpler to manufacture, the magnetic attraction between the two half-couplings creates significant axial force on the bearings, especially during start-up and braking, hence it is less frequently used in practical applications.

The technical advantages of Magnetic Couplings are particularly prominent in harsh industrial environments. Firstly, due to their non-contact transmission characteristics, they transform traditional dynamic seals into completely static seals, achieving zero-leakage transmission, which is revolutionary in chemical waste treatment scenarios with strict leakage requirements. Secondly, Magnetic Couplings possess inherent cushioning and vibration damping characteristics, effectively alleviating impact loads during motor start-up and operation, thus protecting the transmission system from damage. Additionally, this device offers good axial (△x), radial (△y), and angular (△a) compensation capabilities, tolerating a certain degree of installation misalignment and reducing installation precision requirements. Magnetic Couplings can also serve as overload protection devices; when the system torque exceeds the design limit, the inner and outer magnets automatically slip, preventing damage to expensive components in the power transmission chain and acting as a safety coupling.

With the continuous advancement of rare earth permanent magnet material technology (such as Neodymium Iron Boron and Samarium Cobalt), the torque transmission capacity and reliability of modern Magnetic Couplings have significantly improved, leading to their increasingly widespread application in fields such as chemical industry, pharmaceuticals, electroplating, food processing, and vacuum technology. Especially in chemical waste treatment systems, Magnetic Couplings provide innovative solutions to the long-standing problem of transmission seal leakage and improve system stability.

2 Stability Challenges in Chemical Waste Treatment

The chemical waste treatment process faces extremely complex working environments and multiple technical challenges that directly impact the stability and reliability of the treatment system. Chemical waste often contains highly corrosive substances, toxic components, and various heavy metal elements, which pose serious threats to the integrity and functional maintenance of treatment equipment. For example, electrolytic manganese residue (EMR) generated in the electrolytic manganese production process is a typical highly acidic solid waste containing recoverable manganese (content about 4-6 wt%) and various toxic metals such as cadmium and lead. During long-term storage, these substances can migrate into groundwater due to rainfall infiltration, causing serious environmental arsenic pollution.

In traditional chemical waste treatment systems, the sealing reliability of transmission devices is one of the key factors affecting system stability. Taking the continuous neutralization system commonly used in chemical waste treatment centers as an example, this process aims to neutralize acidic waste and perform alkaline precipitation in various metal-containing wastes. Input wastes include acidic waste from storage tanks, miscellaneous inorganic waste, non-chelated ferric chloride etchants, and reduced chromium solution from reduction reactors. These materials are often highly corrosive or contain large amounts of solid particles, posing significant challenges to equipment using traditional shaft seals, such as pumps, agitators, and compressors. Due to wear issues with mechanical seals over long-term operation, corrosive media can easily leak along the transmission shaft, leading to equipment damage, environmental pollution, and even safety incidents.

Special operating conditions in the chemical waste treatment process further exacerbate stability challenges. For instance, when treating arsenic-containing wastewater, the iron-arsenic co-precipitation method is an economical and effective treatment method. However, the arsenic chemical forms in the resulting arsenic-containing industrial slag are complex, and their stability is influenced by multiple factors. Studies show that the stability of arsenic-containing co-precipitates is significantly affected by the final pH of the system – as the system pH increases, the stability of arsenic-containing co-precipitates decreases markedly. The co-precipitates exhibit good stability when the solution is weakly acidic (pH 4 or 5), but poor stability under weak alkaline conditions (pH 8 or 9). Such fluctuations in pH conditions are extremely common in chemical waste treatment processes, requiring treatment equipment to possess excellent corrosion resistance and reliable sealing capabilities.

Furthermore, common vibrations and impact loads in chemical waste treatment systems also affect the long-term stability of equipment. For example, when belt conveyors are used to transport solid residues containing chemical waste, traditional hydraulic couplings generate significant vibration and impact during start-up and operation, causing severe component wear, increased energy consumption, and reduced safety factors. These issues have been fully demonstrated in practices at coal mine transportation stations and similarly exist in chemical waste treatment scenarios.

Another challenge not to be overlooked is the variable load conditions in the chemical waste treatment process. Taking the chromium reduction reactor as an example, during the reduction of hexavalent chromium to the less toxic trivalent state, the reduced material needs to be sent to a continuous neutralization system for precipitation and dewatering. The load characteristics in this process fluctuate with changes in material viscosity, solid content, and the extent of chemical reactions, placing extremely high adaptability requirements on the transmission system. Traditional rigid couplings struggle to effectively handle these variations, often leading to motor overload, system shutdown, or even equipment damage.

The multiple challenges of corrosion, wear, vibration, and load fluctuation faced by chemical waste treatment equipment are interconnected, collectively affecting the long-term stable operation of the entire system. Therefore, developing and applying new transmission technologies to fundamentally address these stability issues has become an urgent technical problem in the field of chemical waste treatment. It is against this background that Magnetic Coupling technology provides an innovative solution to the stability challenges in chemical waste treatment.

3 Magnetic Coupling Solutions and Application Cases

3.1 Solutions for Harsh Environments

Magnetic Couplings, leveraging their unique technical advantages, can effectively address various stability challenges in chemical waste treatment. Their non-contact torque transmission characteristic completely eliminates the dynamic sealing links in traditional transmission devices, fundamentally solving the most troublesome leakage problem in chemical waste treatment. In chemical waste treatment processes, media leakage not only causes equipment corrosion and environmental pollution but also increases maintenance costs and system downtime. Magnetic Couplings achieve complete sealing through a static containment shell, entirely eliminating potential leakage points. This advantage is particularly significant when handling highly corrosive and toxic chemical waste.

The adaptive transmission characteristics of Magnetic Couplings enable them to effectively mitigate vibration and impact problems in chemical waste treatment systems. When the transmission system experiences sudden load changes or torque impacts, the relative slip between the inner and outer magnets of the Magnetic Coupling can absorb these energy fluctuations, preventing their transmission to the motor side, thereby achieving smooth power transmission. This characteristic is particularly important when starting high-inertia equipment (such as large pumps, mixers, or belt conveyors), significantly reducing starting current and minimizing grid impact. For example, the permanent magnet coupler consists of a conductor disc and a magnet disc, with energy transfer achieved through magnetic field coupling between them. This magnetic field coupling connection offers advantages such as vibration isolation, noise reduction, and reduced requirement for installation alignment accuracy.

Additionally, Magnetic Couplings have inherent overload protection functionality. When the driven end jams due to foreign objects or excessive load, causing the torque to exceed the design value, the inner and outer magnets automatically slip, thereby cutting off power transmission and preventing damage to the motor and transmission system. This characteristic is especially crucial when handling chemical waste containing solid particles or prone to scaling, effectively preventing serious consequences such as motor burnout due to equipment blockage.

3.2 Practical Application Cases and Effect Analysis

3.2.1 Application Case: Bulkhead Transmission Device in Offshore Oil FPSO

In the bulkhead pump bulkhead transmission device of a floating production storage and offloading (FPSO) unit in offshore oil production, Magnetic Couplings demonstrated excellent performance. The device originally used diaphragm couplings, which faced severe vibration, corrosion, and seal failure problems in the harsh marine environment. After being retrofitted with Magnetic Couplings, the bearing vibration and temperature of the bulkhead transmission device were significantly reduced, and the failure rate decreased markedly. This improvement not only enhanced equipment reliability but also substantially reduced maintenance costs and system downtime. The successful application of Magnetic Couplings in this offshore oil FPSO bulkhead pump transmission device provides strong justification for their use in similarly harsh environments within chemical waste treatment systems.

The high humidity and high salt conditions in marine environments share significant similarities with chemical waste treatment environments, both capable of causing severe corrosion to traditional transmission equipment. Due to their fully enclosed structure and the use of corrosion-resistant materials like austenitic (304) stainless steel for the containment shell, Magnetic Couplings can effectively resist the erosion of corrosive media. This characteristic makes them particularly suitable for application in acid, alkali, or salt-containing waste treatment systems at chemical waste treatment centers.

3.2.2 Retrofit Case: Belt Conveyor at a Coal Mine Transportation Station

In the retrofit project of the SSJ-1000 belt conveyor at the Silaogou Mine transportation station, permanent magnet couplers replaced traditional hydraulic couplings, solving technical problems such as high energy consumption, low safety factors, and severe component wear. Although this case does not directly involve chemical waste treatment, its technical principles and solutions are fully applicable to solid waste conveyance systems in chemical waste treatment plants.

| Application Scenario | Original Technology | Magnetic Coupler Application Effects | Applicable Chemical Waste Treatment Scenarios |

| Offshore Oil FPSO Bulkhead Pump | Diaphragm Coupling | Reduced bearing vibration and temperature, decreased failure rate | Corrosive chemical waste transfer pumps |

| Coal Mine Transportation Station Belt Conveyor | Hydraulic Coupling | Reduced energy consumption, improved safety factor, decreased component wear | Chemical solid waste transmission systems |

| Catalyst Recovery in Catalytic Cracking Unit | Traditional Mechanical Conveyance | Annual recovery of 500 tons of low-magnetic catalyst, saving about 3.5 million RMB | Recovery of valuable components from chemical waste |

3.2.3 Synergistic Application of Magnetic Separation Technology and Magnetic Couplings

Yangzi Petrochemical introduced magnetic separation technology into the catalytic cracking unit of its refinery, efficiently recovering waste catalysts by separating materials with different magnetic properties under the action of an electromagnetic field. This technology processes an average of 9 tons of waste catalyst per day, directly recycles about 30% of the low-magnetic catalyst, recovers 500 tons of low-magnetic catalyst annually, and saves approximately 3.5 million RMB in costs. Although magnetic separation technology differs in principle and application from Magnetic Couplings, both are based on the principle of magnetic field action, demonstrating the great potential of magnetic technology in chemical industrial waste treatment and resource recovery.

In Yangzi Petrochemical's practice, the complete magnetic separation equipment was skid-mounted on a semi-trailer; catalysts from the waste agent tank were directly fed into the raw material buffer bin via pipeline transport (pneumatic conveyance). Ionized air was used to eliminate static electricity carried on catalyst particles, preventing agglomeration and achieving efficient separation. This modular, mobile design concept can also be borrowed for the application of Magnetic Couplings in chemical waste treatment systems, especially in scenarios requiring flexible deployment or temporary capacity expansion.

# 3.3 Specific Application Schemes of Magnetic Couplings in Chemical Waste Treatment

In chemical waste treatment systems, Magnetic Couplings are mainly applied to rotating equipment such as pumps, mixers, compressors, and conveyors. Taking the continuous neutralization system of a chemical waste treatment center as an example, this system is used to neutralize acidic waste and perform alkaline precipitation in various metal-containing wastes. If the transfer pumps and agitators in such systems adopt magnetic drives, they can completely solve the problem of corrosive medium leakage and significantly improve the long-term stability of the system.

For treating chemical waste containing heavy metals, such as the aforementioned iron-arsenic co-precipitates, whose stability is affected by various factors including system pH value, alkali type, and Fe(III)/As(V) ratio, reliable equipment operation is crucial in these sensitive processes. By providing leak-free, maintenance-free transmission solutions, Magnetic Couplings can ensure the continuity and stability of the treatment process, avoiding treatment interruptions or secondary pollution caused by equipment failure.

Furthermore, in the treatment of electrolytic manganese residue (EMR), integrated magnetic separation and acid/oxidant leaching processes can produce battery-grade manganese sulfate. This recovery process involves a large number of pumps and mixing equipment, with the working medium being highly corrosive and abrasive, making it an ideal application scenario for Magnetic Couplings.

| Stability Challenge | Problems with Traditional Transmission Solutions | Magnetic Coupler Solution | Benefit Evaluation |

| Corrosive Media Leakage | Mechanical seal wear leads to media leakage | Non-contact transmission, static containment shell achieves zero leakage | Reduces environmental pollution, lowers maintenance costs |

| Vibration and Impact Loads | Rigid connection causes vibration transmission, equipment wear | Magnetic coupling cushioning effect absorbs vibration and impact | Extends equipment life, reduces downtime |

| System Overload Risk | Overload causes equipment damage, motor burnout | Magnetic slip effect, automatic overload protection | Prevents serious failures, improves system safety |

| Installation Alignment Difficulty | Alignment errors cause premature failure of bearings and seals | Good axial, radial, angular compensation capability | Simplifies installation process, reduces installation costs |

4 Solution Implementation Guide

# 4.1 Selection and System Integration of Magnetic Couplings

To successfully apply Magnetic Coupling technology in chemical waste treatment systems, scientific selection methods and integration strategies must be followed. Firstly, torque capacity is a key parameter for selecting a Magnetic Coupling. The maximum torque requirement in system operation, including starting torque, acceleration torque, and peak torque, must be accurately calculated. The rated torque of the Magnetic Coupling should be slightly higher than the system's maximum working torque to provide appropriate overload protection margin, while avoiding cost increases due to over-engineering. For variable load applications common in chemical waste treatment systems, such as variable frequency drive pumps or mixers, the torque transmission characteristics of the Magnetic Coupling under different slip conditions must also be considered.

Secondly, the speed range and slip characteristics significantly impact system performance. The speed of a permanent magnet Magnetic Coupling can be adjusted by changing the air gap length between the conductor disc and the magnet disc. This speed regulation capability is very useful in chemical waste treatment processes. For example, in a continuous neutralization system, adjusting the agitation rate based on inflow and pH fluctuations can optimize reaction conditions and save energy. When selecting a Magnetic Coupling, it is necessary to confirm whether its allowable maximum speed and speed regulation range meet the process requirements.

Environmental adaptability is another key consideration in the selection process for chemical waste treatment systems. The containment shell material of the Magnetic Coupling must be able to resist corrosion from the process media. For most chemical waste treatment applications, austenitic stainless steel (such as 304 or 316L) or higher-grade corrosion-resistant alloys (such as Hastelloy) are recommended for the containment shell material. Furthermore, the selection of permanent magnet material is also crucial. Neodymium Iron Boron (NdFeB) permanent magnets have high magnetic energy product but may require surface protection in high-temperature or corrosive environments; Samarium Cobalt (SmCo) permanent magnets have a higher operating temperature range and better corrosion resistance, making them suitable for more demanding conditions.

In terms of system integration, Magnetic Couplings need to seamlessly connect with existing equipment bases and control systems. For new projects, flange-mounted Magnetic Couplings can be considered for direct connection with standard pumps, fans, or mixers. For retrofit projects, custom adapter sleeves may be needed to replace the original coupling without moving the equipment base. In the retrofit case of the belt conveyor at the Silaogou Mine transportation station, using a permanent magnet coupler instead of a traditional hydraulic coupling not only solved the problems of high energy consumption and low safety factor but also significantly reduced component wear. This successful experience can provide a reference for the retrofit of similar equipment in chemical waste treatment systems.

4.2 Installation and Maintenance Key Points

Correct installation is the foundation for ensuring the long-term stable operation of Magnetic Couplings. Although Magnetic Couplings have higher tolerance for axial, radial, and angular misalignment than mechanical couplings, it is still necessary to follow the manufacturer's recommended installation accuracy to maximize equipment life and transmission efficiency. Basic installation steps include: cleaning all mating surfaces, checking dimensional fits, using special tools for alignment adjustment, and tightening bolts according to the specified torque values.

The maintenance requirements of Magnetic Couplings are much lower than those of mechanical seal devices, but regular condition inspections are still necessary. The recommended maintenance schedule includes monthly checks of equipment vibration and noise levels, quarterly checks of bearing temperature and containment shell integrity, and a comprehensive annual disassembly inspection to clean accumulated debris in the magnetic gap and check for demagnetization of the permanent magnets. It is important to note that the demagnetization risk of Magnetic Couplings increases with rising temperature, so operating temperature must be monitored to ensure it does not exceed the maximum allowable working temperature of the permanent magnet material.

In chemical waste treatment systems, fault diagnosis of Magnetic Couplings can rely on some obvious signs. For example, a continuous decrease in output torque may indicate partial demagnetization of the permanent magnets, while increased vibration might suggest bearing wear or increased misalignment. Modern intelligent Magnetic Couplings can integrate temperature sensors, vibration sensors, and torque monitoring systems to monitor equipment status in real time, providing data support for predictive maintenance. This intelligent functionality holds significant value in chemical waste treatment systems requiring high reliability.

4.3 Economic Benefits and Return on Investment Analysis

Applying Magnetic Coupling technology in chemical waste treatment systems, although involving a higher initial investment than traditional transmission solutions, offers significant economic benefits throughout the entire lifecycle. Taking Yangzi Petrochemical's introduction of magnetic separation technology to recover waste catalyst as an example, the project recovers 500 tons of low-magnetic catalyst annually, saving about 3.5 million RMB in costs. Although this is not a direct benefit of Magnetic Couplings, it reflects the economic value brought by advanced magnetic technology in industrial environments.

The economic benefits of Magnetic Couplings mainly come from the following aspects:

- Maintenance Cost Savings: Magnetic Couplings require no lubrication and reduce the replacement frequency of vulnerable parts such as mechanical seals and bearings, significantly lowering daily maintenance costs and downtime.

- Energy Consumption Optimization: The high-efficiency transmission and soft start characteristics of Magnetic Couplings can reduce system energy consumption, especially in variable speed applications where the energy-saving effect is more pronounced compared to valve or damper throttling methods.

- Environmental Risk Reduction: By completely eliminating leakage paths, Magnetic Couplings avoid cleanup costs, environmental fines, and potential legal liabilities caused by chemical waste leakage.

- System Reliability Improvement: Reduced unplanned downtime and production interruptions increase the overall availability and processing capacity of the chemical waste treatment system.

Return on investment analysis should comprehensively consider these factors and calculate them in combination with the expected equipment life. In most chemical waste treatment applications, the investment payback period for Magnetic Coupling technology is between 1-3 years, depending on factors such as operating time, energy consumption level, and administrative costs.

5 Future Prospects

The application prospects of Magnetic Coupling technology in the field of chemical waste treatment are broad. With the continuous development of materials science, manufacturing processes, and intelligent technology, this technology is evolving towards higher efficiency, greater reliability, and smarter functionality. The following development directions deserve special attention in the future:

The development of high-performance permanent magnet materials will directly enhance the performance limits of Magnetic Couplings. Although widely used Neodymium Iron Boron permanent magnets have excellent magnetic properties, their temperature stability and corrosion resistance still need improvement. New generations of rare earth permanent magnet materials, such as Samarium Cobalt composite materials and thermally stable Neodymium Iron Boron, can maintain stable magnetic performance at higher temperatures (>250°C) and in harsher chemical environments, greatly expanding the application range of Magnetic Couplings in high-temperature chemical waste treatment processes.

The integration of intelligent monitoring systems with Magnetic Couplings is another important development trend. By embedding micro-sensors in the inner or outer rotor to monitor real-time operating parameters such as torque, temperature, vibration, and slip of the Magnetic Coupling, and combining them with big data analysis and machine learning algorithms, predictive maintenance and intelligent energy management of the equipment can be achieved. Such intelligent Magnetic Couplings can automatically adjust the air gap or magnetic circuit configuration to optimize system energy efficiency and provide early warnings before potential failures occur, maximizing the reliability and operational efficiency of chemical waste treatment systems.

The expansion of Magnetic Couplings into new application fields is also promising. Currently, Magnetic Couplings are mainly used in standard equipment such as centrifugal pumps, fans, and belt conveyors. In the future, they are expected to be extended to more types of chemical waste treatment equipment, such as screw pumps, gear pumps, compressors, mixers, and centrifuges. Especially in electric submersible equipment (like submersible pumps), various vacuum technologies, and deep-sea oil rigs, Magnetic Couplings also have broad application space. As the serialization and standardization of Magnetic Couplings improve, they are expected to serve as a new type of universal basic component, providing more complete supporting solutions for the chemical waste treatment industry.

Furthermore, the synergistic application of Magnetic Couplings with other magnetic technologies also shows great potential. For example, the magnetic separation technology introduced by Yangzi Petrochemical, which separates materials with different magnetic properties through electromagnetic field action, forms a good complement to Magnetic Coupling technology. In future chemical waste treatment systems, more technology combinations based on magnetic principles may be seen, such as the integrated application of magnetic transmission, magnetic separation, and magnetic stabilization, providing more comprehensive and efficient solutions for chemical waste treatment.

From a broader perspective, the advancement of Magnetic Coupling technology will directly support the resource recovery and circular economy development in chemical waste treatment. Taking the treatment of electrolytic manganese residue as an example, integrating magnetic separation with H₂SO₄/H₂O₂ synergistic leaching processes can produce battery-grade MnSO₄·H₂O, with the final product meeting the HG/T 4823-2023 Grade I metal impurity limits. In such high-value-added resource recovery processes, the reliable, leak-free transmission guarantee provided by Magnetic Couplings ensures the continuity and stability of the entire process chain, providing key technical support for the transition of chemical waste from "treatment" to "resource recovery."

In summary, Magnetic Coupling technology, with its unique non-contact transmission advantages, can effectively solve stability challenges in chemical waste treatment, offering significant value in improving system reliability, reducing maintenance costs, and eliminating environmental risks. As this technology continues to mature and application experience accumulates, it will undoubtedly play a more important role in the field of chemical waste treatment, promoting the development of the chemical industry towards a safer, more envi.