Optimizing Drive Systems: A Technical Analysis of Standard vs. Extended Filling Chamber Fluid Couplings

2025-12-03 11:08Title: Optimizing Drive Systems: A Technical Analysis of Standard vs. Extended Filling Chamber Fluid Couplings

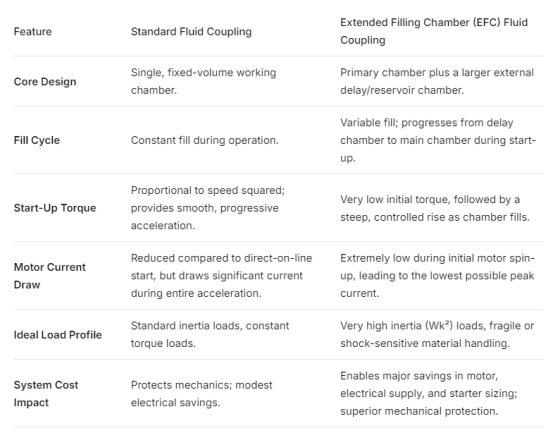

In the realm of industrial power transmission, the Fluid coupling stands as a cornerstone technology for reliable and flexible torque transfer. This elegantly simple device, utilizing the kinetic energy of a hydraulic fluid to transmit power, is indispensable for protecting motors, managing start-up sequences, and dampening load shocks across countless applications. However, not all Fluid coupling units are created equal. This press release provides a detailed comparison between the fundamental standard Fluid coupling and its advanced derivative, the Extended Filling Chamber (EFC) Fluid coupling, elucidating their distinct operational principles, performance characteristics, and ideal industrial use cases.

The Standard Fluid Coupling: The Pillar of Simplicity and Reliability

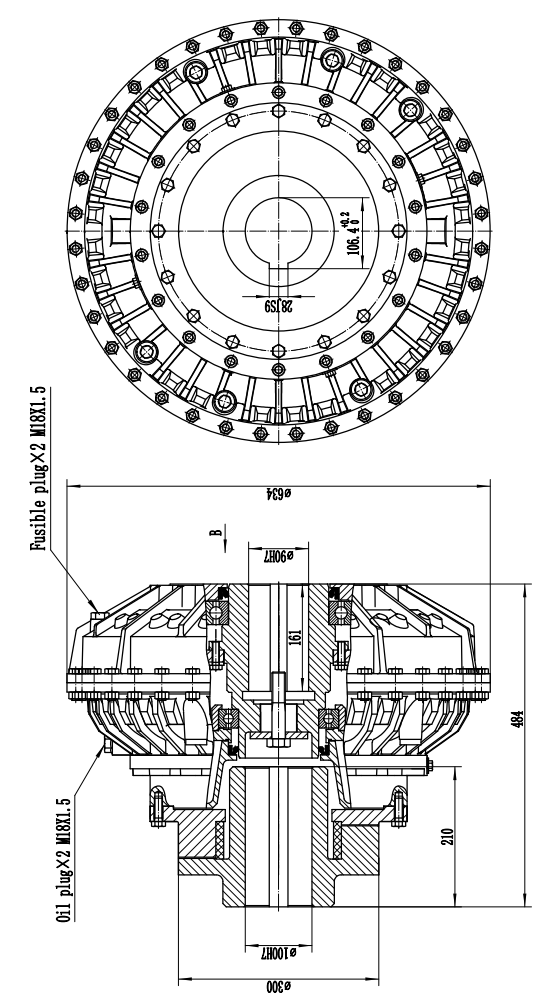

The conventional Fluid coupling is comprised of three primary components: an impeller (pump wheel) connected to the input shaft, a runner (turbine wheel) connected to the output shaft, and a sealed casing that houses these elements and contains the precise volume of working fluid, typically oil. Its operation is elegantly straightforward. As the motor drives the impeller, centrifugal force accelerates the fluid outward. This high-velocity fluid stream then strikes the blades of the runner, transferring kinetic energy and inducing rotation, thereby driving the connected load.

The core advantages of this standard Fluid coupling are its mechanical simplicity, cost-effectiveness, minimal maintenance requirements, and robust construction. It provides several critical benefits:

Smooth, Controlled Acceleration: It eliminates harsh mechanical shock during start-up by progressively accelerating the load, significantly reducing stress on belts, chains, gears, and other mechanical components.

Inherent Overload Protection: In the event of a severe jam or overload, the Fluid coupling will slip, limiting the torque transmitted to the motor and preventing damage. The motor can continue to run without stalling.

Vibration Damping and Misalignment Compensation: The fluid medium absorbs torsional vibrations and accommodates minor shaft misalignments, leading to smoother operation and extended equipment life.

Even Load Distribution in Multi-Motor Drives: When driving a single load with multiple motors, a Fluid coupling on each motor ensures near-equal torque distribution between them.

Primary Applications of the Standard Fluid Coupling:

This type of Fluid coupling is perfectly suited for a vast array of general industrial applications involving standard inertia loads. Common uses include:

Conveyor systems of moderate length and capacity.

Centrifugal pumps and fans.

Mixers, agitators, and some crushers.

Basic machine tool drives.

For these scenarios, the standard Fluid coupling offers an optimal balance of performance, protection, and value, making it the most widely deployed form of Fluid coupling globally.

The Extended Filling Chamber (EFC) Fluid Coupling: Engineered for High-Inertia Challenges

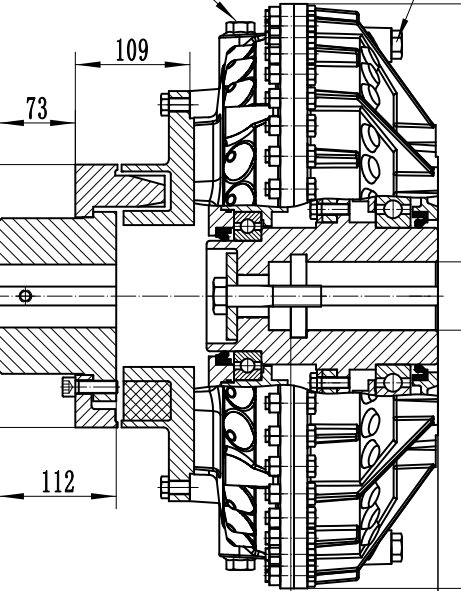

The Extended Filling Chamber Fluid coupling, often referred to as a delayed-fill or variable-fill coupling, represents a sophisticated evolution of the basic design. Its key differentiating feature is an additional, concentric outer chamber or reservoir that is significantly larger in volume than the main working circuit. This "delay chamber" is connected to the primary cavity through carefully calibrated passages or valves.

The operational principle is ingeniously different. During the initial start-up phase, the majority of the working fluid is retained within this outer delay chamber. Consequently, the main working circuit between the impeller and runner is only partially filled, resulting in very low torque transmission—a state akin to a "soft start" in its most extreme form. As the input speed increases, centrifugal force gradually transfers the fluid from the delay chamber into the active working circuit. This causes a controlled, often non-linear, increase in transmitted torque, which can be tailored to specific load requirements.

The transformative advantages of the EFC Fluid coupling are most apparent under demanding conditions:

Severe Separation of Motor and Load Acceleration (Motor "No-Load" Start): It allows the driving motor to accelerate rapidly to near its operating speed with minimal load torque. Only after the motor reaches high RPM does the load begin to accelerate in a controlled manner. This drastically reduces motor starting current (often by over 50%), minimizes voltage dip on the electrical supply network, and reduces thermal stress on the motor.

Optimized Drive System Economics: By dramatically lowering the peak current demand, it enables the use of smaller, lower-cost motors, transformers, and electrical switchgear. The reduced mechanical shock a

lso allows for lighter, more economical downstream mechanical components.

Superior Control for Extreme Loads: It provides unparalleled smoothness and control when accelerating massive, high-inertia loads, preventing belt slip on conveyors and minimizing gear train shock.

Primary Applications of the Extended Filling Chamber Fluid Coupling:

This advanced Fluid coupling is the definitive solution for applications characterized by extremely high inertia or where electrical network constraints are a concern. Its typical applications include:

Long-distance, high-capacity overland conveyor belts and steeply inclined conveyors.

Ball mills, rotary kilns, and large crushers in mining and cement industries.

Large induced-draft or forced-draft fans in power plants.

Drum motors and other applications where a very soft, delayed start is mandatory.

Comparative Summary: Selecting the Right Fluid Coupling

Expert Commentary

"Understanding the distinction between these two types of Fluid coupling is fundamental to proper drive system design," states a veteran application engineer in the power transmission sector. "The standard Fluid coupling is a superb, all-purpose protective element. However, when project specs involve massive inertia or limited electrical infrastructure, the EFC Fluid coupling transitions from an option to a necessity. Its ability to decouple motor acceleration from load acceleration is a game-changer for both operational reliability and capital expenditure. Specifying the correct Fluid coupling technology is one of the most effective decisions for optimizing total cost of ownership."

Conclusion and Industry Outlook

From its foundational role in standard machinery to its critical function in enabling the efficient start-up of some of the world's most massive material handling and processing equipment, the Fluid coupling remains a vital component in industrial engineering. The choice between a standard and an Extended Filling Chamber Fluid coupling hinges on a detailed analysis of the load's inertia, the electrical system's capabilities, and the desired start-up profile. As industries worldwide push for greater energy efficiency, reduced mechanical wear, and smarter asset management, the advanced capabilities of the EFC Fluid coupling are seeing increased adoption. By leveraging the appropriate Fluid coupling technology, plant managers and engineers ensure not only the smooth and safe operation of their equipment but also achieve significant long-term savings in energy and maintenance, solidifying the Fluid coupling's position as an indispensable asset in modern industrial drive trains.