Industrial Shift: Comparing Oil-Based and Water-Based Fluid Couplings in Modern Machinery

2025-10-22 08:57Subtitle: Efficiency, Safety, and Environmental Trade-Offs Drive Material Selection in Hydraulic Coupling Systems

Introduction

In the realm of industrial machinery, fluid couplings (also known as hydraulic couplings) serve as critical components for transmitting power between engines and work equipment. These devices, which rely on either oil or water as their working medium, have sparked debates among engineers regarding efficiency, safety, and environmental impact. As industries prioritize sustainability and cost-effectiveness, understanding the distinctions between oil-based and water-based fluid coupling systems becomes essential. This article explores their structural differences, operational advantages, and limitations, drawing on technical insights from hydraulic transmission experts.

1. Fundamental Working Principle of Fluid Couplings

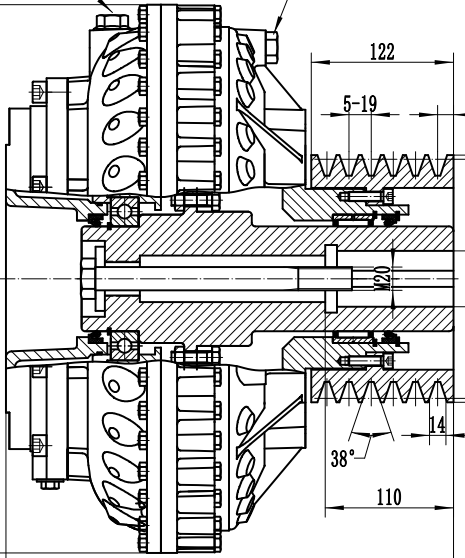

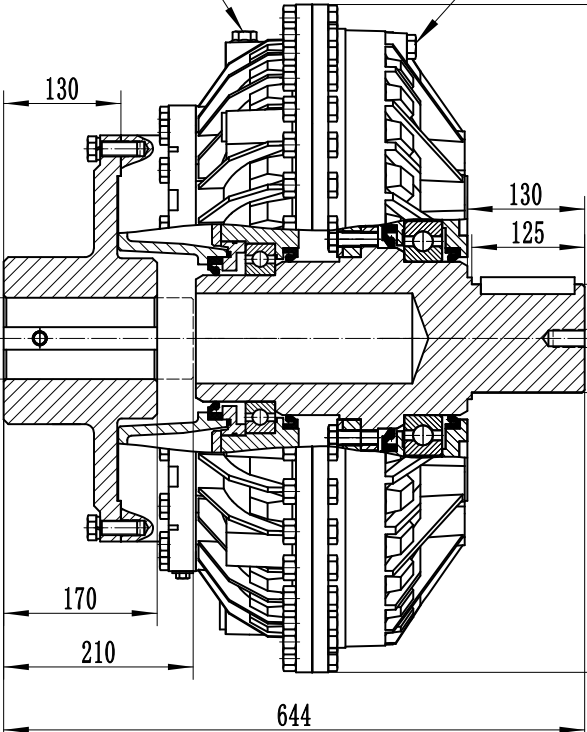

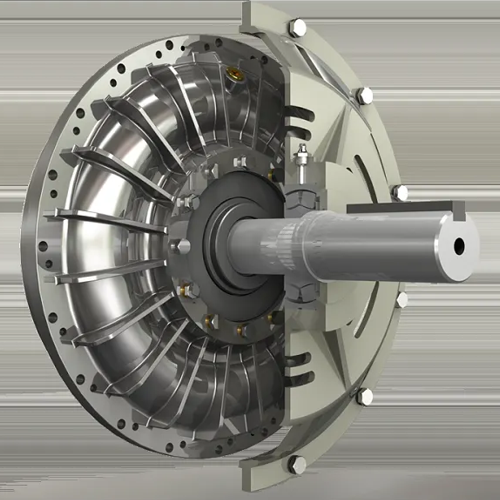

A fluid coupling is a non-rigid hydraulic device that transfers torque through kinetic energy transmitted via fluid momentum-2-5. Its core components include:

Pump Wheel: Connected to the input shaft (e.g., an engine), it converts mechanical energy into fluid kinetic energy.

Turbine Wheel: Linked to the output shaft, it transforms fluid energy back into mechanical motion.

Sealed Chamber: Houses the working medium (oil or water) and facilitates circular fluid flow between the wheels-5.

The process operates on centrifugal force: as the pump rotates, fluid accelerates outward, striking the turbine blades and driving the output shaft. This design enables smooth starts, overload protection, and vibration damping-2-3. However, the choice of fluid medium drastically alters performance.

2. Oil-Based Fluid Couplings: Reliability and Widespread Adoption

Oil-based hydraulic couplings dominate industries like mining, metallurgy, and heavy machinery due to their lubricity and stability-2-5. Key features include:

High Efficiency: Transmission efficiency reaches 96–98% under optimal conditions-4.

Thermal Management: Oil’s high boiling point minimizes vaporization risks, reducing pressure buildup.

Durability: Oil lubricates internal components, minimizing wear on bearings and seals-1.

However, oil-based systems face challenges:

Flammability Risk: In high-temperature environments, oil poses fire hazards.

Environmental Pollution: Leaks contaminate soil and water, rendering them unsuitable for food, pharmaceutical, or textile sectors-1-8.

Cost: Mineral oils require periodic replacement and waste disposal.

3. Water-Based Fluid Couplings: Eco-Friendly but Technically Complex

Water-based fluid couplings leverage water’s abundance and non-toxicity, making them ideal for environmentally sensitive applications. According to industrial studies-1-8:

Power Transmission: Water’s density allows 1.15x higher power transmission compared to oil.

Sustainability: Water is non-polluting and cost-effective, aligning with green manufacturing goals.

Industry Applications: Commonly used in coal mining, food processing, and chemical plants where oil contamination is unacceptable-1.

Despite advantages, water-based systems incur critical drawbacks:

Pressure Explosion Risks: Water vaporizes at high temperatures, causing steam pressure buildup. Without relief mechanisms like explosive plugs and fusible alloys, catastrophic failures may occur-1.

Corrosion and Seal Failure: Water vapor infiltrates bearings, accelerating rust and reducing lifespan. Internal components require anti-corrosion coatings, raising production costs-8.

Structural Demands: Casings must withstand up to 3.4 MPa pressure, increasing material usage and manufacturing complexity-1.

Lower Reliability: Mean time between failures (MTBF) often falls below 2,000 hours in harsh conditions-1.

4. Key Comparison: Oil vs. Water as Working Media

AspectOil-Based Fluid CouplingWater-Based Fluid Coupling

Efficiency96–98% efficiency-4Slightly lower due to vaporization

SafetyStable but flammableExplosion risks; requires dual safety valves-1

Environmental ImpactPolluting; unsuitable for clean industriesEco-friendly; ideal for regulated sectors-8

CostModerate initial investmentHigher maintenance and corrosion prevention-1

LifespanLonger due to better lubricationShorter under humid/high-temperature conditions-8

5. Industry Trends and Future Outlook

The hydraulic coupling market is evolving toward hybrid solutions. While oil-based systems remain prevalent in heavy industries, water-based fluid couplings gain traction in eco-conscious sectors. Innovations include:

Advanced Seals: Nanomaterial coatings to prevent water vapor leakage.

Smart Monitoring: Sensors detecting pressure spikes and auto-triggering coolant systems-3.

Bio-Oils: Degradable oils bridging the gap between safety and sustainability.

However, experts note that fluid coupling systems face competition from magnetic drives and direct-drive technologies in low-power applic

ations-3-6.

6. Conclusion

The choice between oil and water-based fluid couplings hinges on specific operational needs. Oil offers reliability and efficiency in harsh environments, while water prioritizes environmental safety despite technical compromises. As industries strive for greener practices, advancements in material science and automation will shape the next generation of hydraulic coupling systems. Engineers must weigh trade-offs in power transmission, safety, and total cost to optimize performance across diverse applications.